ANNEXURE 2

Particulars of Conservation of Energy, Technology Absorption and Foreign Exchange Earnings and Outgo

[In terms of Section 134 (3) (m) of the Act read with Rule 8 of the Companies (Accounts) Rules, 2014, forms part of the Board's Report for Fiscal 2017]

- CONSERVATION OF ENERGY

The Company has always been conscious of the need for conservation of energy and Energy Conservation (ENCON) projects are implemented at all the plants and offices of the Company in a planned and budgeted manner. Some of the major ENCON Perojects in Fiscal 2017 include:

- The steps taken or impact on conservation of energy:

- Change over the direct heating process in joint sealant baking oven in paint shop.

- Installation of LED lights for various applications areas like streetlights, vehicle storage pads, office and shop floor

- Providing fans and blower instead of ASPs at TCF shops

- Implementation of 3C1B process in Paint Shop

- Change from soft starter to VFD for paint booth exhaust blowers

These efforts have resulted in electrical energy saving of 105.18 lakh kWh, fuel saving – Natural Gas 277 MT, Propane 159 MT. The whole effort resulted in cost savings for the Company of around Rs. 8.82 crores and annual CO2 emission reduction of 9,099 tCO2e.

- The steps taken by the Company for utilizing alternate sources of energy:

- The Company owns a 'captive wind power' project of 21.95 MW capacity. Pimpri Plant utilized Captive Wind Energy generation of 2.81 crore units (equivalent CO2e Reduction of 23,042 tCO2e). In Fiscal 2017, Pune Plant procured third party Wind Power of 2.65 crore units (equivalent to 21,730 tCO2e reduction), this resulted in net savings of Rs. 27.36 crores in electricity charges, whereas Sanand Plant, procured third party Wind Power of 1.25 crore units (equivalent to 10,269 tCO2e reduction) and Dharwad Plant, procured third party Wind Power of 0.27 crore units (equivalent to 2276 tCO2e reduction) in Fiscal 2017.

- In Fiscal 2017, Pune Roof Top Solar PV Power Plant of 1.8MWp capacity, generated 0.27 crore Kwh (equivalent to 2236 tCO2e reduction) with net saving of Rs. 0.64 crores in electricity charges. Whilst Sanand Roof Top Solar PV Power Plant of 2.0MWp capacity, generated 0.28 crore Kwh (equivalent to 2327 tCO2e reduction), Lucknow and Dharwad Roof Top Solar PV Power Plant generated 26,678 and 6,580 kWh of power respectively.

- Renewable Energy Certificate (REC): the Company 21.95MW Wind Power Project is registered under REC scheme. Auction of 9,493 RECs resulted in net saving of Rs. 1.4 crores for Fiscal 2017. Cumulative RECs generated 63,432 RECs out of which 50,010 RECs was sold through auction and cumulative benefit was Rs. 7.25 crores.

- The capital investment on energy conservation equipments:

The Company has invested about Rs. 9.24 crores for achieving energy conservation results.

Award/Recognition received during the year is as below,

- The Company's Dharwad Plant received GreenCo "Gold Rating" and Lucknow Plant received CII GreenCo "Silver Rating". GreenCo is a Factory based rating process, which uses 10 parameters to evaluate the energy and environmental performance.

- The Company's CVBU Pune Plant and Jamshedpur Plant was adjudged as "Excellent Energy Efficient Unit Award" at CIINational Award for Excellence in Energy Management - 2016, in Automobile Manufacturing category. The National Excellence in Energy Management Awards are given to industries of various sectors.

- The Company's PVBU Pune (Car Plant) won National Award for Excellence in Water Management 2016 and FICCI Water Award for Excellence in Water Management and Conservation in "Industrial Water Use Efficiency".

- On occasion of World Environment Day - 5th June 2016, Jharkhand State Pollution Control Board adjudged the Company's Jamshedpur Plant First in industry category for Environmental Initiatives.

- Jamshedpur Plant received CII-GreenCo Best Practices Award 2016 for its' Innovative Project on "Water Conservation"

- TECHNOLOGY ABSORPTION, ADAPTATION AND INNOVATION

- Efforts made towards technology absorption, adaptation and innovation

Presently automotive industry is facing unprecedented volatility in the technology environment coming from regulations, from emergence of new business models and the way in which the customer will access the future mobility solutions. The Company is working in technology domain of domains of xEVs, Hybrids and Fuel Cell in addition to technology upgrades on conventional IC engines to be able to meet regulations. The Company is also working on various other areas to support connected vehicles and creating value for customers which would make the vehicle offerings attractive. With an overarching theme to support all upcoming regulations and technology developments to support future products, the Company has a well-defined technology strategy.

To foster innovation, the Company is in process of setting up various innovation hubs that would be very lean and agile. These hubs themselves will operate in a startup mode with focus on testing of solutions and go-to-market strategies. The setting up of the first of these centers is already underway in the Silicon Valley (US) and UK.

For example of technology programs that the Company is concentrating on are:

- Composites, light weighting and fuel efficiency improvement related technologies.

- Combustion optimization and thermal efficiency improvement projects in collaboration with academia and consortia.

- Alternate fuels technologies CNG, Dual fuel, Hydrogen.

- Hybridization, xEVs and associated technologies.

- Efficient engine cooling technology.

- Advanced technologies for vehicle NVH refinement

- Internet of things (IoT) and associated technologies on connectivity like Apps, telematics, diagnostics, analytics, etc.

- Benefits derived as a result of the above efforts

The Company's continued efforts in the technology domains is manifested by the market launch of products. In passenger cars, showcased Nexon and Tigor in Geneva International Motor Show 2017 and has launched 3 cars – Tiago, Hexa and Tigor – which received critical recognition from both customers and automotive media. In commercial vehicles, company has made good progress in Hybrid and Electric buses and is trying to secure tender based orders from relevant authorities. The Company also showcased its innovation project called Racemo which reinforces its efforts towards connected car and uses a patented Moflex MMS Structural Technology.

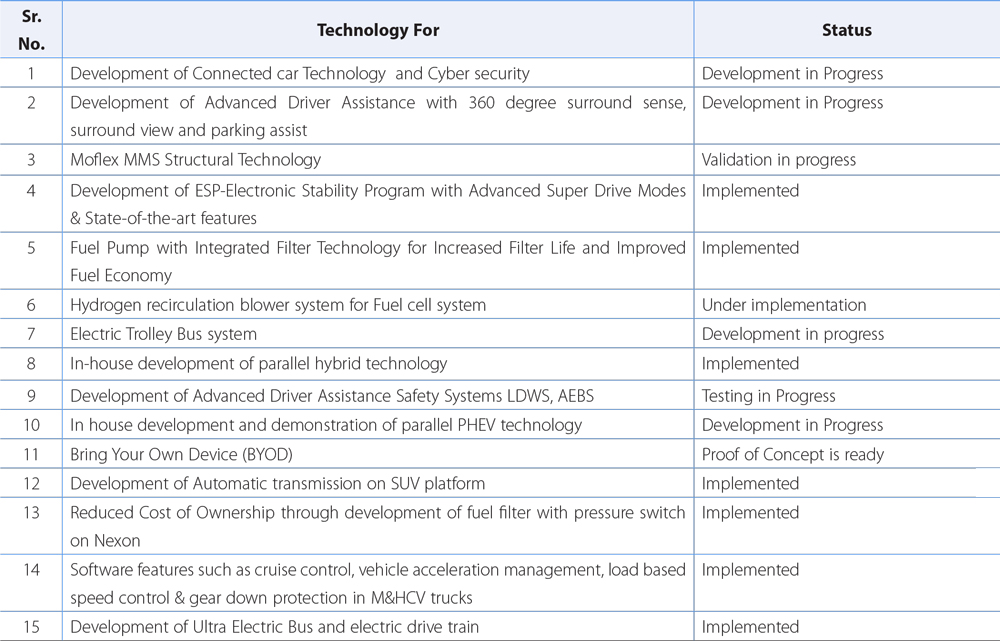

Major technology absorption undertaken during the last year includes:

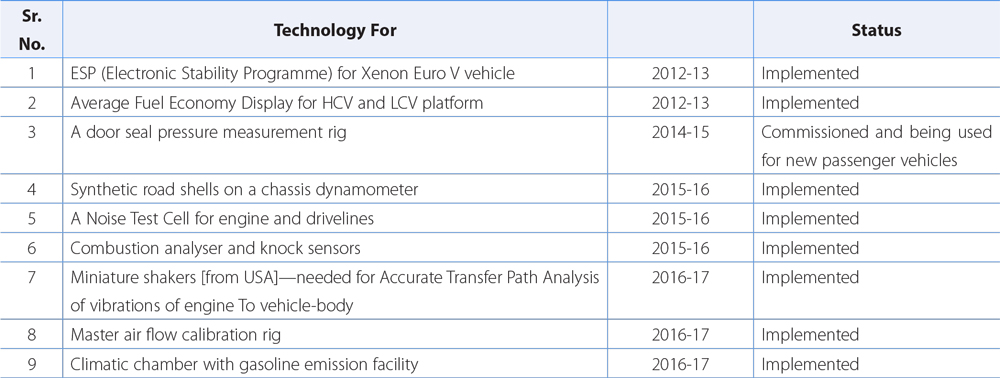

- Major Technology Imports includes (preceding 3 financial years):

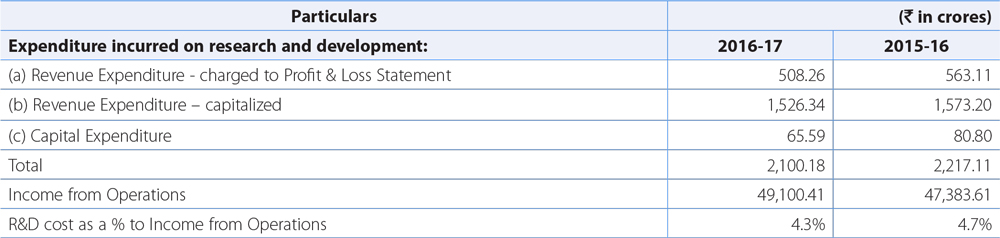

- Research and Development