- Specific areas in which R & D is undertaken

- Robust control system for hybrid and electric buses and electric cars

- Electrification of vehicle accessories for electric buses

- Development of indigenous Li-Ion battery packs for hybrid and electric buses and electric cars

- Indigenous development of fuel cell systems and accessories

- Development of high efficiency motors and inverters

- Development of electrically driven thermostat, fan, oil pump, turbocharger on various engine platforms which improve fuel economy and overall performance of vehicle

- Increased drain intervals for oil for axle and gear box inline with implemented for engines

The Company is mainly focused on specific areas of R&D and Engineering by which it can strengthen its HorizoNext Philosophy. For passenger cars, the main focus areas are in the domain of creating stunning design, pleasurable driving experience and connectivity. Therefore, the R&D portfolio is aligned towards developing technologies, core competence and skill sets in these specific domains to secure impactful and timely delivery of the envisaged future product products with leading product attributes. For commercial vehicles, in addition to design, the main focus areas are total cost of ownership, to be a market leader in application specific fuel efficiency and to deliver high performance and reliable products. Focus areas of Company’s R&D also evolves around R&D infrastructure development and being timely future ready for future emissions and vehicular safety norms.

As one of India’s largest R&D spenders, the Company focuses on connected, electric, shared and safe mobility and is aligned with local and global trends. To enhance in-cab experience, an in-built air freshening system has been developed. A new generation of infotainment products are being developed, that includes the next generation ConnectNext platform. It adapts Android Auto and Apple Carplay following with Android automotive operating systems that brings consumer world into the car infotainment system. We continually strive to offer our customers best – in class experience and take feedback from JD power surveys.

Tata Motors along with its subsidiary, TMETC has developed a fully autonomous car as part of the UK Auto drive project. This research initiative ensures that Tata Motors remains among the forefront of autonomous driving technology. To offer consumers a safer, smarter and convenient future.

Further to the above technologies, the Company is exploring Emergency Call, a solution that will contact emergency services in the event of an accident. The system will share GPS location to ensure time critical assistance. Tata Motors constantly strives to renew customer experience, hence focusing on solutions such as innovative seating configurations, express cooling, electronic parking brakes are few of the areas under focus.

Some of the forward-looking R&D programs that the Company is concentrating on are:

Benefits derived as a result of the above R&D

Such efforts on R&D have secured a host of benefits for the Company in terms of being up-to-date with state of the art on technology front strengthening the Company’s position in commercial vehicles and would contribute in repositioning and transforming passenger vehicles to compete at a global level.

The Company’s R&D spanning across over a decade of design effort in developing series hybrid bus, the Company has won the order to deliver 25 diesel series hybrid electric vehicles to the Mumbai Metropolitan Regional Development Authority (MMRDA), the largest order for hybrid buses in India till date. Once the hybrid buses start running in Mumbai, the Company expects further orders from other cities.

Through focused in-house development of technology, the Company is able to offer new technology products at more affordable prices compared to global equivalent products. For example, we won tenders for Electric buses and Electric cars from Govt of India on a global basis in which our products were offered at the lowest cost. The indigenously developed fuel cell buses would be far cheaper than the fuel cell buses available from a handful of global bus manufacturers, if put to production. The strength of the Company's approach to R&D in alternate powertrain is that the aggregates are globally sourced, but the overall system integration is done in-house to ensure that the final product serves the customer needs optimally and at lower price points. The Company is also putting efforts in indigenization of EV aggregates and fuel cell aggregates.

Targeting the booming Indian e-commerce sector, the Company has developed trucking solutions, including vehicles with customised payloads and deck lengths and vehicles equipped with advanced features such as OTP lock, CCTV cameras, load sensors, telematics system. The Company showcased 13 fully built, readyto-use vehicles at ‘The e-Commerce Expo 2019’ in Mumbai. Reiterating its commitment to the Swachh Bharat Mission, Tata Motors showcased its Integrated Waste Management Customised Solutions at the MUNICIPALIKA 2018 event from September 19- 21, 2018 at the Bombay Exhibition Center.

During FY 2019, we filed 86 patent applications and 113 design applications. In respect of applications filed in earlier years, 104 patents have been granted and 37 designs registered. Both filing and grant details include national and international jurisdictions.

Future Plan of Action

We plan to continue our endeavor in the research and development space to develop vehicles with reduced cost, time to market and shorter product life cycles. One of the main initiatives in this direction would be a platform approach to create bills of material and bills of process that have a high degree of commonality to reduce complexity and enhance ability to scale. The Company aims for timely and successful conclusion of technology projects so as to begin their induction into mainstream products, which will lead to a promising future. Our Focus is going to be building technology, capability, scale & capacities in R&D to able to ride the emerging trends. We are now focusing more on accelerated testing and validation and are using a lot of digital tools for the simulation process. The Company has charted a massive jump from 181st rank last year to 2nd rank in India’s Most Attractive Brands 2018. Tata Motors has been able to stay ahead of the curve and create superior offerings for the customer. Our keen eye for digitisation, connectivity, automation and advanced regulations' compliance is helping us deliver exciting innovations to our customers worldwide. On current product portfolio, the enhancements are offered through an approach of modular architecture strategy, enhanced Powertrain solutions, light weighting, system efficiency improvement strategies etc

Innovation at the Engineering Research Center (ERC)

At Tata Motors while using different initiatives to strengthen the creative potential of our Business units and R&D team in ERC, we also work with the external Eco-system of suppliers, technology companies and startups to leverage their know how, creativity and out of the box thinking. Internally we have introduced formats like Innoverse and Imagineering, where ideas are crowdsourced and developed in proof of concepts through an accelerated development and maturation process, to Ideathon, on the lines of a hackathon.

These focus both on the traditional technologies as well as the emerging ones that allow us to deliver on the 4 disruption vectors impacting the automotive industry namely CESS (Connected, Electrified, Shared and Safe). These developments then find their way into product programs in a structured manner, of moving from limited proof of concepts to a fully engineered and deployable outcome.

Externally we have launched the TACNet program – Tata Motors Automobility Collaboration Network https://tacnet.tatamotors. com to connect and engage with technology companies and start-up community. Through this platform we post business challenges for which we are seeking solutions, as well as invite companies with innovative futuristic solutions to reach out to us for collaborative working.

- Mobility Services

Building on the work started over the last couple of years, Tata Motors is looking at addressing the emerging and evolving needs of the markets and customers it serves through augmented products, service model offerings and mobility solutions. This not only allows us to serve our existing customers better, but also bring new customers to the Brand whose needs were not being catered to with our current offerings. Inline with the Vision statement, Mobility solutions across People and Goods movement will form a key part of our strategy and market offering. This will be done selectively through both investments as well as collaborations as an engagement model and explore through multiple on ground pilots before scaling the successful ones.

The Company will continue to invest in R&D as well as collaborative projects which will enhance the competitiveness of it's future products and will also start active research in upcoming areas of automotive technology like autonomous driving, connected cars, and others.

Tata Motors plans to focus in the following areas to meet future product portfolio needs

- Telematics and connected solutions entering into smart city era powered by 5G

- Enhancing user experience with natural voice recognition and smart access systems

- Improving vehicle efficiency and alternate propulsion systems through light-weight structures

- Advanced driver assistance systems that increase occupant safety and convenience

- Digital Product Development Systems Initiatives

- Connected Vehicle platform (CVP) core strategy has been finalized for standardizing and modularizing on-vehicle electronics, enhanced reuse to achieve economies of scale, leveraging synergy at dealership and service network and IoT based technology development.

- Modular BOM approach initiated in design and manufacturing domain to increase flexibility and minimize complexities.

- Implementation of online systems for improving tracking, signoffs, reporting and analysis by digitalization of 60 business processes based on homegrown pFirst platform. Major systems implemented in areas of VA/VE, WCQ, Program Management and budget tracking across functions.

- 40 new knowledge based engineering applications were designed and implemented across various product design and safety domains such as, Rear Parking Assist System Analysis (RPAS), Digital Validation of initial CAS surface carried out for its exterior projections to reduce bodily injury risk to a person in the event of a collision.

- More than 150 new productivity enhancement tools were developed and implemented across various product design and validation domains which assists our large number of engineers to increase productivity significantly through identified levers such as enhanced quality checks for design, drawing automation and process automation.

- For reducing number of parts and to increase reuse of parts across platforms, 3D feature based part search tool is integrated into parts creation and release process. Process is enhanced by providing information of other enterprise data and augmented with analytics for speedy decision.

- Critical manufacturing processes were validated digitally during BS-VI development with simulation including ergonomic analysis to detect potential problems in early stages of planning. MOST time analysis is being done extensively for MOP (Measure of Performance) improvement on the shop floor.

- Automotive Body Fastener design process is enriched by implementing in-house developed body fastener authoring tool for BIW designers.

- Next Generation Smart Assembly Management framework was designed and developed by using Smart User Defined Function/ Feature (UDF) and Smart Constraints for CVBU UDF based assembly design methodology. 6 UDF based Smart Assembly application were delivered for Air brake systems and fuel system design groups.

- Product design quality and manufacturing quality is enhanced by implementing Dimensional Variation Analysis (DVA) by simulating product design and manufacturing process.

- To make information available to right stakeholders at right time, latest technology of BOTs based apps are deployed for multiple functions helping them verify data and take informed decisions.

- Deep Learning artificial intelligence (AI) based algorithms and apps are introduced into design process to reduce physical testing cycles by building predictive models helping in closing the gap between physical & digital simulations.

- High Performance Computing (HPC) infrastructure is augmented by adding 2 new HPC systems. CAE simulation using General Purpose Graphics Processing Unit (GPGPU) computation technology.

- Deployment of satellite servers across all plant locations, architected with high redundancy with almost zero downtime for applications deployed on a large number of virtual servers delivering high performance compliant to security standards of ISO27001.

- Implemented SIEM (Security Information and Event Management) Application, which collects, stores and analyses logs from different sources including servers, network devices and security devices, centrally monitoring security threats in real time for quick attack detection and response with holistic security reporting and compliance management.

Front loading of product creation, validation & testing and seamless information dissemination are major contributors to ‘Time to Market’ and ‘World Class Quality’ initiatives to improve product development process.

Significant improvements in key processes for product design and manufacturing planning domain through modification of existing processes identifying few manual processes and converting into digital domain for better quality and agility.

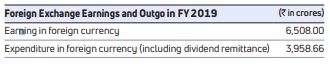

- FOREIGN EXCHANGE EARNINGS & OUTGO

- The Company participated in key Global motor shows and conclaves such as the Bhutan Construction Expo, Fexpocruz (Bolivia), Bangkok Motor Show, Dhaka Automotive Show, Malaysia, Philippines, Thailand Defence Expo.

- Ultra was launched in Malaysia, LPT 1212 in Bangladesh, CR range of intermediate and light commercial vehicles were launched in Bhutan. Signa series was launched in Bangladesh & Mozambique, Prima 3338 range of tippers in Indonesia, Super Ace mint E4 in Philippines and Vietnam, Ace Mega XL in SAARC and SE African markets, Magna in Bangladesh & Tanzania, Elanza in Oman and E4 models in Sri Lanka.

- CVIB conducted ‘Global Service Campaign’ in more than 40 countries in 3rd week of November, 2018 as a part of the enhancing the Customer Connect. The service campaign saw more than 50,000 vehicles serviced during the campaign.

- Bagged several prestigious orders, including order for 200 un from Myanmar Armed Forces, 400 units from AFTU Senegal, 450 Buses from ILOC Ivory Coast, etc.

- TATA Motors successfully delivered 200 units of LPTA 715 4x4 Troop Carrier to Myanmar Armed Forces.

- The 5th edition of the Company One World - International CV Distributor meet was held in Dubai from 25th to 23rd February, 2019. This year’s event saw attendance by the Company Senior Management and over 200 guests from across 35 countries.

- Launch of new models in Nepal and Bangladesh helped the Company to the No. 4 and No. 3 rankings in the respective markets

- In Nepal, the Tata Motors’ brand is at position ‘Four’ after competing with 26 Passenger Vehicle brands, with 11.8% market share. Tigor remains the No. 1 Sedan in Nepal with 22.2% Share, Sumo the No. 1 MUV with 47.1% Share. TML also has a No. 1 Share in Ambulance with 81.5% Share. Nexon is No. 2 in CUV with share of 31% in Nepal.

- In Bangladesh, the Company secured ‘Market Leader Position’ in cars segment with 23.7% Share. Tata Motors made the first ever supply to Bangladesh Army with 18 units of Hexa

- The Company participated in the prestigious Geneva Motor Show in Switzerland for the 22nd successive year where the Tata Altroz electric hatch, H2X concept, Buzzard Geneva Edition, Buzzard sport and Altroz premium urban car were displayed. The Company also participated in Nepal Automobile Dealers’ Association (NADA) Auto Show and the Dhaka Automobile show where we achieved sales of 125 vehicles against 54 in FY2018.

- The Company participated in Rainstorm Emergency Relief activity carried out by SIPRADI CSR wing in Support with Tata Trust & Tata Motors. 65 families got relief package in this activity

Activities relating to exports

The Company exported 53,140 vehicles comprising 51,119 CVs and 2,021 PVs. Export initiatives and highlights include:

Commercial Vehicles

Passenger Vehicles

Development of export markets

ASEAN and NW Africa are the Company’s focus regions for future growth. Indonesia, Vietnam, Philippines and Malaysia are steadily picking up with the Tata Motors’ brand becoming more visible in these markets. Our shipments to NW Africa increased by 31% in FY 2019 as compared to FY 2018, making it the fastest growing region. Vehicle assembly, in Vietnam saw steady growth of numbers. We also started assembly for Super Ace and Ultra in Malaysia in FY 2019.

The Company has been expanding its relevance in markets it is present in, with the introduction of new products such as Tata Prima, Ultra, Signa trucks and Buses in key markets to further grow volumes. The Company re-established its presence in the markets of Tanzania and Bhutan

Export Plans

The Company plans to focus on growing its exports aggressively in identified geographies by offering customer centric products and strong after sales support

On behalf of the Board of Directors

N CHANDRASEKARAN

Chairman

(DIN: 00121863)

Mumbai,

May 20, 2019