HOLISTIC APPROACH TO VALUE CREATION

At the Tata Motors Group, we are committed to creating value for all our stakeholders by adopting an ‘integrated thinking’ approach. We believe our financial performance is as important as our non-financial performance.

Did you know?

Tata Motors’ CSR interventions extend much beyond India. The Tata Motors SkillPro programme reached out to youth in Bangladesh, Mozambique, Sudan, Tanzania, Kenya, Nigeria, Ghana and Sri Lanka.

JLR

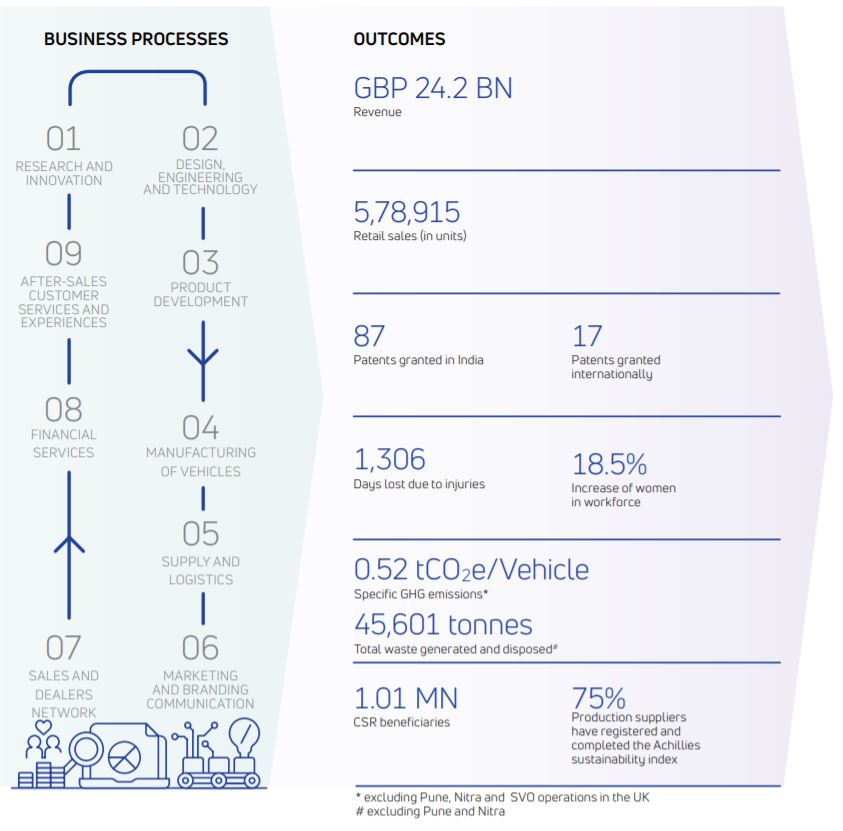

APPROACH TO DESTINATION ZERO

JLR is driven by its commitment of providing premium quality experience to customers, ensuring sustainable profitable growth for investors, creating a happy, healthy and future-ready workforce, building stronger communities and minimising the environmental footprint. JLR's vision for Destination Zero is to enhance the overall quality of life by achieving zero emissions, zero accidents and zero congestion.

Conserving natural capital

JLR's responsible business imperatives drive its towards Destination Zero. JLR's commitment towards responsible corporate citizenship drives its continuous investments in people and communities.

DESTINATION ZERO

JLR is on a journey to Destination Zero – a world of zero emissions, zero accidents and zero congestion. Its ambition is to make societies safer and healthier and the environment cleaner through relentless innovation, adapting our products and services to the rapidlychanging world.

Zero emissions

Through the introduction of more electrified products and the relentless innovation of its Ingenium petrol and diesel powertrains, JLR's continually seek to reduce tailpipe CO2 emissions. JLR is on track to deliver a 45 % reduction in European fleet average tailpipe CO2 emissions by 2020 versus 2007. JLR’s concerted efforts towards creating modern, clean and efficient combustion engines will continue to play a crucial role in its complete transition to electric mobility from 2020.

Zero accidents

JLR, in collaboration with UK Autodrive, is conducting trials on next stage self-driving technologies, on test tracks as well as on complex, busy routes in UK cities. Self-driving Range Rover prototypes are already capable of negotiating traffic lights, parking themselves and avoiding vehicle hazards while avoiding pedestrians and other road users.

Zero congestion

JLR is testing the Green Light Optimal Speed Advisory (GLOSA) system, a new vehicle-to-everything (V2X) technology designed to communicate with traffic lights to find the optimal driving speed that minimises frequency of stops at traffic junctions. Reducing harsh acceleration and sudden braking comes with positive environmental benefits, in the form of improved air quality.

JLR is committed to reducing its environmental footprint by consuming natural resources responsibly. JLR is also focused on reducing emissions of its products. Globally, JLR has doubled production while halving emissions from its manufacturing sites.

DECARBONISING OPERATIONS

JLR’s UK manufacturing assembly and production development sites were verified as Carbon Neutral, from April 2017 to March 2018. JLR continues to purchase 100 % renewable, zero carbon electricity at its core UK sites, as well as its manufacturing plant in Slovakia.

REDUCING VEHICLE EMISSIONS

Through the introduction of electrified products and innovation of Ingenium petrol and diesel powertrains, JLR aims at reducing tailpipe CO2 emissions. All Jaguar Land Rover models meet the standards required by the RDE testing procedure. From January 2020, RDE2 will require vehicles to emit 80mg/km NOx or less. The Evoque is the first luxury compact SUV to achieve this standard.

Circular economy and consumption of materials

JLR takes a ‘whole systems thinking’ approach towards design, sourcing, manufacturing, and recycling of vehicles. While focusing on aesthetics, JLR tries to utilise materials that are sustainable and capable of delivering industry benchmarks in that direction.

Understanding and addressing customer needs

JLR strives to meet the everevolving needs of customers. The emergence of connected technologies has facilitated large-scale customer data mining for analysing and understanding the needs, routines and habits of JLR's customers.

Managing supply chain responsibly

JLR maintains a sustainable, resilient supply chain at all its manufacturing locations and ensures all its tier-1 suppliers are ISO14001 certified.

JLR’s latest project, REALITY builds on its long-standing work – 2016’s REALCAR initiative – and finds innovative ways to recover aluminium from end-of-life vehicles to build next-generation models. It uses natural fibres and premium recycled materials to reduce environmental impact

For example, the GO I-PACE app uses Artificial Intelligence to help customers understand how the Jaguar I-Pace would fit their lifestyle. Safety of customer data is of utmost importance.

The tier-1 suppliers are also required to uphold the highest standards of business ethics, environment management, human rights and working conditions, as prescribed by JLR's Code of Conduct. In addition, 75 % of JLR’s component suppliers submit their sustainability performance measures to the Achilles data management system.

Moreover, JLR’s employees took an initiative to reduce the use of single-use plastics and managed to save more than 1,100,000 m2 of plastics going to the environment. Through this initiative, JLR also managed to save money and improve health and safety.

CIRCULAR ECONOMY IN PRACTICE

The new Range Rover Evoque interior features eucalyptus textile made from 30 per cent natural wool fibres, along with polyurethane fabric, creating a durable yet lightweight material.

Engaging in community development

JLR engages with its communities worldwide to address their needs through innovative solutions, funding and technology.

COUNTERING FOOD POVERTY IN UK

JLR’s Solihull manufacturing plant initiated a large-scale community project on a waste ground allotted for the programme. The scheme aims at providing fresh produce to the people facing food poverty in and around Solihull and Birmingham. It builds on the plant’s existing relationship with Gro Organic, an organisation dedicated to creating green spaces while providing social and economic opportunities for the most disadvantaged people in the region. Now in its second year, the project brought together 30 of JLR’s volunteers who contributed 270 volunteering hours to clean and prepare the land. The project has already provided 20 boxes of fresh food to the local community and will continue to contribute through food banks, schools and churches.

JAGUAR LAND ROVER CHINA CHILDREN – YOUTH DREAM FUND

From 2014, the Fund focused on helping underprivileged children to realise their potential. In its second phase since 2018, the Fund intends to provide exposure to creative education, social care and ChinaUK cultural changes to children and has reached out to more than 50,000 kids.

DELIVERING SHARED VALUE IN NITRA

During FY 2018-19, JLR employees donated ~500 volunteering hours to complete a series of CSR projects in Nitra, Slovakia. Working with the city council, JLR helped renovate public spaces and building while addressing the needs of children with disabilities. JLR also delivered educational programmes and created an endowment fund that will provide long-term support to the city and its people.

HELPING IMPROVE NATURAL ENVIRONMENT IN BRAZIL

In Brazil, at the commencement of manufacturing operations, JLR planted trees on one hectare (ha) of its land , as part of recreating the natural forest. It is now embarking on planting trees on another 1 ha of its land.

TECHNOLOGY FOR GOOD

JLR’s engineers have developed a door that opens automatically to improve usability for people with limited mobility.

CRATES TO CLASSROOMS

Undertaken by the employees of JLR’s Pune facility, the Company under this initiative has donated 700 desks to seven schools around the plant location. Now in its fourth year, the programme with the help of a carpenter is upcycling used pallets and crates into desks for disadvantaged children.

Creating diverse and future-ready workforce

JLR endeavours to provide the right platform for its employees to learn and grow, and has taken several initiatives in that direction.

PARTNERSHIP WITH RED CROSS

JLR's worldwide partnership with the Red Cross has funded 20 humanitarian projects in 25 countries since 2013 reaching over 1.1 million people

JAGUAR LAND ROVER ACADEMY

The Academy is founded on the principle of lifelong learning, from recruitment to retirement. All employees, irrespective of age, background or career stage, can be part of the Academy. The training programmes at the Academy primarily include Science, Technology, Engineering and Maths (STEM); and last year provided ~17 lakh hours of training

PROMOTING DIVERSITY IN ENGINEERING

JLR runs specific programmes for supporting ex-armed forces personnel, and for creating employee networks for gender equality, Lesbian, Gay, Bisexual and Transgender (LGBT) communities and black professionals. It also facilitates training to help employees overcome unconscious biases. JLR runs specific education, apprenticeship and undergraduate programmes to encourage more women to study STEM subjects and pursue engineering careers.

PROVIDING SAFE WORK ENVIRONMENT

JLR has a defined vision to shape future mobility – Destination Zero – zero emissions, zero accidents and zero congestion. JLR harnesses new technologies to enable smart integrated mobility and improve lives in the communities it calls home. JLR is adopting circular economy principles throughout product creation processes, with active reuse and recycling as well as application of innovative sustainable materials. JLR also focuses on employee well-being, including mental health. With the launch of the ‘let’s have the conversation’ programme, it supports open discussions on matters of mental health. Third party audits were conducted for OHSAS 18001 during FY 2017-18 within all the UK manufacturing locations, and JLR maintained its accreditation to this standard through a series of external assessments. It plans to migrate to the new International Standard ISO 45001.