ANNEXURE 3

Particulars of Conservation of Energy, Technology Absorption and Foreign Exchange Earnings and Outgo

[Pursuant to Section 134 (3) (m) of the Act read with Rule 8 of the Companies (Accounts) Rules, 2014]

- CONSERVATION OF ENERGY

- Steps taken or impact on conservation of energy:

- Jamshedpur Plant: Use of Glow Plug device in place of LPG in Heat Treatment, Optimising HT furnace operation for crown wheel processing, Optimizing FDV (Forced Draft Ventilation) unit operation running in VFD (variable frequency drive) modes, Reduction in propane consumption in Long Member PT-CED Ovens by installation of Flux Maxiox (fuel saving device) and optimizing shell temperature of Ovens through regular energy audits

- Pimpri Plant: Converting 8500 Nos. of 36W fluorescent tubes to 18WLED tubes, Optimized equipment running by proper shift management.

- Chinchwad Plant: Replacement of 500 Nos. of 400W high bay lamps with 300 Nos. of 120W LED fixtures, Separation of compressed air supply to Grey Iron and Aluminium Foundry to reduce energy consumed by Compressors.

- Maval Foundry: Yield Improvement projects on Moulding Line, Reduced heating time through integral heater core box design for all new core boxes.

- Lucknow Plant: Reduction in compressed air consumption and AC power consumption at Plant level.

- Pantnagar Plant: Reduction in compressed air consumption at Plant level, Installation of VFDs on 75KW exhaust blowers of Paint Booths, Start-up time reduction in ASU Burners in Surfacer and Base Coat booth, Streamlined production planning for metallic color batch painting.

- Dharwad Plant: Fuel conservation by improvements in start-up of ACC oven.

- Chikhali Plant: Optimization of line running in Press & Weld Shop as per production plan.

- Sanand Plant: Optimising running hours of ASU Chillers, VFD

for ED circulation pumps, Magnetic Fuel Saver, Arresting heat

leakages in all Paint Baking Ovens.

These ENCON efforts in fiscal 2019 have resulted into - energy savings of 1,07,415 GJ (76,185 GJ power + 31,230 GJ fuel), avoided emission of 20,218 tCO2e and cost savings of INR 1,834 lakhs. - Steps taken for utilizing alternate sources of energy:

- The Company has set up Renewable Energy generation capacity (solar and wind) which includes:

- In FY 2019, the in-house RE capacity was enhanced by 2MWp Roof-top Solar PV installations each at Lucknow and Pimpri Plants and by 0.5 MW at Chinchwad, Pune, which will help offset GHG emissions in the coming FY’19-20. The Company sources off-site wind power at its Pune, Sanand and Dharwad Works through Power Purchase Agreements (PPA) with Third Party Wind Power Generators and will continue to source renewable power from the grid in line with regulatory policies / frameworks and tariffs in the States of operations. Taking this further, the Company has signed a Power Purchase Agreement (PPA) with M/s Tata Power Renewable Energy Ltd. (TPREL) for setting up an additional 7 MWp capacity of roof and ground mounted solar photovoltaic (PV) installations across Jamshedpur, Pantnagar and Dharwad Plants.

- In FY 2019 the Company generated / sourced 94.30 million kWh of renewable electricity for its manufacturing operations, contributing to avoidance of 77,333 tCO2 e and financial saving of Rs.39.12 Crores.

- Capital investment on energy conservation equipment:

- Lucknow Plant won the “Uttar Pradesh State Energy Conservation Award 2018” (under Industries General Category having connected load 1MW and above), - a State level competition conducted by Uttar Pradesh New and Renewable Energy Development Agency (UPNEDA).

- CV Pune won the “Renewable Energy Excellence End User Award 2018” at Renewable Energy India Awards 2018 - Asia’s largest Renewable Energy Expo organized by UBM India.

- CV Pantnagar Plant won the “Golden Peacock Award for Energy Efficiency 2018” organized by Institute of Directors.

- CV Pune and Pantnagar Plants recognized as “Excellent Energy Efficient Unit” at the CII National Award for Excellence in Energy Management 2018. CV Pune and CV Pantnagar Plants were also among only 3 units awarded “National Energy Leader” in the ‘Automobile & Engineering’ Sector.

- Jamshedpur Plant recognized as “Energy Efficient Unit” at the CII National Award for Excellence in Energy Management 2018.

- Jamshedpur Plant received 4.5/5 Star rating at the CII Energy Conclave-2018 organized by CII –Eastern Region.

- Pantnagar Plant was certified ‘PLATINUM’ under CII’s “GreenCo Rating” system in 2018. Pantnagar Plant was originally rated ‘GOLD’ in 2015.

- Sanand Plant was certified ‘PLATINUM’ under CII’s “GreenCo Rating” system in 2018

- TECHNOLOGY ABSORPTION, ADAPTATION AND INNOVATION

- Efforts made towards Technology Absorption, Adaptation and Innovation

- Continuous & increased focus for fuel efficiency improvements across engine platforms through parasitic loss reduction, electrification of accessories, etc.

- Guided diagnostics coupled with connectivity solutions across identified engine/vehicle platforms

- Participation in a consortium led by a US research firm, for thermal efficiency improvement of diesel engines

- Advanced HMI technologies for improved user experience

- Advanced occupant safety and driving convenience adapted to Indian driving conditions

- Advanced connectivity architecture to support future mobility driven features

- Advanced vehicle efficiency through light-weighting of body and chassis structures, higher efficiency aggregates

- Digital validation development of full vehicle multi-body dynamic model for engine mounting system to validate attributes in the lab

- Development of full vehicle multi-body dynamic model for simulation of PAT targets for engine mounting system

- Brake disc temperature rise simulation for multi-stop applications

- Tire component target cascading simulation for vehicle ride and handling (ongoing)

- Engine vibration frequency calculation and simulation in ADAMS for improved NVH

- A new approach for powertrain multi-attribute target development & balancing for vehicle integration

- Mathematical model of powertrain for the passenger vehicle with Front Wheel Drive (FWD) is in development to address torsional vibrations

- Model development and analysis of effect of various steering, suspension and tire parameters on steering dynamic behavior

- Effect of suspension bush stiffness on vehicle K&C Attributes

- Vehicle SPMM & Handling Attribute Simulation

- Methodology Development for Brake Squeal Simulation using Abaqus FEA Software and Appropriate Squeal Reduction Strategy.

- Development of simulation methodology for predicting tire durability.

- Methodology development of engine mount target cascading and design optimization to meet NVH PAT

- Benefits derived as a result of the above efforts

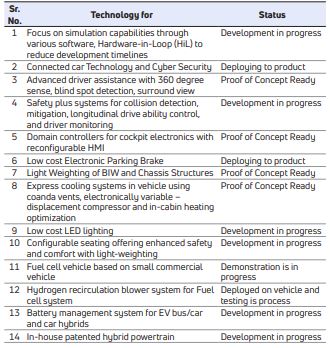

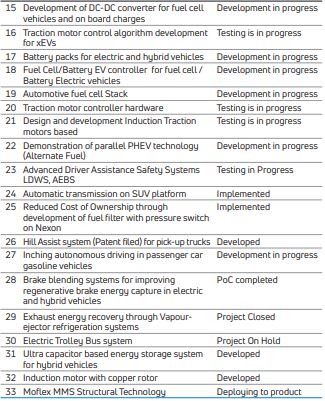

- Major technology absorption initiative undertaken:

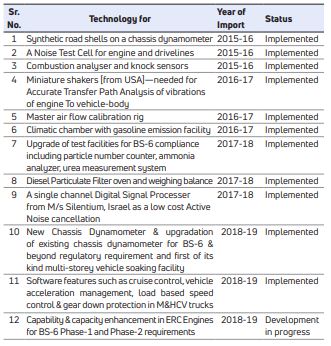

- Major Technology Imports includes (preceding 3 financial

years):

- Major technology absorption initiative undertaken:

The Company has always been conscious of the need to conserve energy in its Manufacturing Plants which leads to optimized consumption of non-renewable fossil fuels, energy productivity, climate change mitigation and reduction in operational costs. The Company is also signatory to RE100 - a collaborative, global initiative of influential businesses committed to 100% renewable electricity, and is working towards massively increasing the demand for RE deliverables.

Energy Conservation (ENCON) projects have been implemented at all Plants and Offices of the Company in a planned and budgeted manner. Some of the major ENCON Projects in FY 2019 include:

- 21.95 MW Captive Wind Power Plant (off-site) at Supa and

Satara in Maharashtra;

- 3.8 MW Roof-top Solar PV installation at Pimpri & Chikhali (Pune);

- 2 MW Roof-top Solar PV installation at Sanand;

- 2 MW Roof-top Solar PV installation at Lucknow;

- 18.5 kWp Solar PV installation at Pantnagar; &

- 7.2 kW hybrid-wind and solar installation at Dharwad

In FY 2019, the Company has invested Rs.333.22 lakhs in various energy conservation projects.

Awards / Recognition received during the year is as below

The Company used a three-horizon strategy for managing its engineering and technology initiatives. The first-horizon involves products that the Company is working on currently, to bring to the market. The second-horizon involves researching known technologies that the Company may not be entirely familiar with at present, but are needed for our future products. And the third-horizon is for ‘blue sky’ research projects and there are a number of projects aimed at fostering a culture of innovation in the Company. The main endeavor is to continuously keep scanning for innovative projects in the third and second horizon and to integrate the promising ones to main stream projects in the first horizon.

Besides, its own ecosystem spanning across India, the UK and Italy, the Company also has tie-ups with various Universities based out of India, University of Warwick in the UK, and joint efforts with institutions in the United States. In India, as part of its efforts in this area the Company has signed a Memorandum of Understanding with IIT Bombay and College of Engineering Pune to undertake collaborative research on live projects and to create a technological partnership.

For example, some of the forward-looking technology programs that the Company is concentrating on are:

Sustainable mobility solutions are the focal point of the global automotive industry. Strict emission norms, crash safety requirements and congestion is resulting in mobility transformation. The challenges faced by the Indian automotive industry remain the same, pressure from regulation and customer affordability. The Company aims to deliver well engineered, safe, advanced cars to the market. The company’s future technology pipeline focuses on four key pillars namely Smart Autonomous & Connected vehicle, Clean Vehicle, Capable Vehicle and Desirable vehicle. To kindle innovation, Tata Motors is setting up lean and agile innovation hubs. These hubs which will operate like startups with focus on testing of solutions and go-to-market strategies. The first of these centers was established in Palo Alto, California.

Key areas of technology engagement in line with global and Indian trends:

Tata Motors is participating in the Govt of India initiated Ucchatar Avishkar Yojana (UAY) project with IIT Kharagpur and Indian Institute of Science (IISC), Bangalore through which indigenous technology for battery packs, traction motors and engineering solutions for system integration is being developed. TML is also collaborating with academic institutions like IISc Bangalore and IIT Bombay for indigenous development of power electronics converters, fuel cell accessories, control algorithm for battery management system and heat exchanger for fuel cell applications.

Tata Motors believes in bringing academia and industry together for advancements in automotive research. Recent research conducted with Birla Institute of Technology & Science, Pilani, Vellore Institute of Technology- Chennai, Vishwakarma Institute of Technology, Pune & other leading technical institutes include:

The Company continues to strengthen its capabilities across the technology domains to meet emerging and future market needs. By careful selection of advanced engineering and future technology portfolio, the Company intends to capitalize and bookshelf the developed technology for incorporation into future products for making them more exciting and more attractive to the end customers.

The Company also endeavors to mitigate all future risks related to technology by timely having appropriate emerging technology on Emissions, FE enhancement, Powertrain, Safety, connectivity, Infotainment, telematics, green initiatives etc., to meet and exceed all future emissions and vehicular safety norms.

In passenger vehicles, the Company’s continued efforts have translated into successful product launches and concept unveils. Earlier launched Tata Nexon is already the winner of several awards. It bagged the honor of becoming 1st engineered & made in India Car with 5-Star Global NCAP safety crash test rating scoring 5 stars for Adult Occupant Protection and 3 stars for Child Occupant Protection. This is a huge landmark in Indian car safety.

With the recently launched Tata Harrier, the Company entered the premium mid-size SUV segment. In a week of its launch, the Tata Harrier bagged the award for ‘Most Awaited Car of the Year 2019’, at the Exhibit Auto Tech Awards. Tata Motors also added to its passenger vehicle family the Tata NRG with SUV inspired styling in the entry-level cross-hatch segment.

In commercial vehicles, an updated version of the original segment defining SCV Tata Ace was launched as Tata Ace Gold offering enhanced ergonomics, safety and comfort. In the Intermediate Light Commercial Vehicle Category, the Next Gen range of Ultra World trucks were launched early last fiscal.

Continued efforts have ensured that Tata Motors bagged the prestigious Autocar “2019 Manufacturer of the year”, under challenging market circumstances.