ANNEXURE - 2

Particulars of Conservation of energy, Technology absorption and Foreign exchange earnings and outgo in terms of Section 134(3)(m) of the Act read with Rule, 8 of the Companies (Accounts) Rules, 2014, forming part of the Directors' Report for the year ended March 31, 2015.

- CONSERVATION OF ENERGY

The Company has always been conscious of the need for conservation of energy and has been sensitive in making progress towards this end. Energy conservation measures have been implemented at all the plants and offices of the Company and special efforts are being put on undertaking specific energy conservation projects like:

- The steps taken or impact on conservation of energy:

- Installed Waste Heat Recovery System to recover waste heat from exhaust flue gases of paint baking oven, reduced thermal losses in furnaces, Optimization of shift operation of Ovens at Foundry, Use of Low Temp Degreasing chemical at Paint Shop, Conversion of Electrical Heating into Natural Gas Heating system for washing machines.

- Installation of Energy Efficient LED Batten fittings for Task lighting and LED High bay for General Lighting, Use of 54Wx4 T5 lamps for shop lights, Installation of energy savers in lighting circuits, Installation of LED street lights, Installation of LED low bays fittings, Switching Off unwanted lights, Installation of Star Rated AC systems.

- Use of Energy Efficient Pumps, Energy Efficient Compressed Air Nozzles, Use of New Technology of Auto Pouring System for Metal at Foundry, Installation of runner risers breaking Machine to reduce the size of runners, risers charged in Foundry furnaces.

- Reduced Pressure of Compressed Air Supply to shops, use of portable small compressors for low compressed air requirement on holidays, Isolation valves for individual bays in compressed air network, Downsizing of motors, Elimination of Motors and Delta to Star conversion of Motors, Fresh air Blower replaced by Air Circular Fans.

- Installation of Variable Frequency Drives for various applications like Blowers, Pumps & Air supply plants' Motors as a flow control strategy for energy conservation.

- Use of motion sensors & timers for on-off control of lighting system and Fresh Air blower operation, Modification in electrical logic for automatic switching On-Off operation of hydraulic motors, coolant pumps, blowers etc., Optimization of AC plant operations, Optimized operation of Panel AC systems, Use of Wind Ventilators.

These changes have resulted in Electrical energy saving of 1.74 crores units, Fuel saving - Diesel 62.6KL, LPG/Propane 707MT and Natural Gas 1.43 Lakh SCM. The whole effort resulted in cost savings for the company of around Rs. 16.79 crores & annual CO2 emission reduction 17,198 tCO2e.

New initiatives like implementation of Sofi software system for Energy and Environment Performance Monitoring and Key Performance Indicator Dashboard to Management is in process.

- The steps taken by the Company for utilizing alternate sources of energy:

- The Company's Endeavour for tapping wind energy has also made significant contributions.

- Company's own 'captive wind power' projects of 21.95 MW capacity. With this, Company's CVBU Pimpri Plant utilized total Wind Power Generated. Wind Energy generation of 2.6 crores units (equivalent CO2e Reduction of 24,435 tCO2e) for Fiscal 2015, this resulted in net savings of Rs. 16.35 crores in electricity charges. Also Company's PVBU Sanand Plant utilized wind energy of 0.545 crores units (equivalent CO2e Reduction of 4,466 tCO2e) purchased through TPTCL for Fiscal 2015, this resulted net savings of Rs. 0.38 crores in electricity charges.

- Renewable Energy Certificate (REC): Company's 21.95MW Wind Power project is registered under REC scheme. Cumulative 58,558 RECs generated; out of which 28,829 RECs sold through auction, cumulative benefit of Rs. 4.15 crores.

- 1st Roof Top Solar PV Power Plant of 223KWp has been commissioned at TATA MOTORS, Pune on 1st April 2015 at H-Block Rooftop. The 223KWp Solar Power is being generated and fed into the system, similar installations of 1.5 MWp capacities are in progress at D, E & C-Block, ERC Mains Building, HR-Block & K-Block Office (PVBU).

- The capital investment on energy conservation equipments:

Company has invested Rs. 4.55 crores for achieving these results.

Awards/Recognitions received during the year is as below:

- CVBU-Pune and PVBU-Pune have been rated GOLD under the CII-GreenCo - Green Company Rating System. Tata Motors is the first Automobile Company in India to be rated under the CII-GreenCo rating system and achieve GOLD rating in the process. About 39 Companies have been rated by CII so far. Senior Leadership of CV and PV have received the award (plaque and certificate) from Mr. Suresh Prabhu, Former Union Power Minister and Chairperson, Council of Energy, Environment and Water, India at the GreenCo Summit.

- Dharwad Plant has bagged the "2nd Prize" of National Energy Conservation Award 2014, in Automobile Manufacturing category by Bureau of Energy Efficiency (BEE), Ministry of Power, Government of India. The National Energy Conservation Awards were given to industries of various sectors at the hands of the Hon'ble Union Minister of Power Mr. Piyush Goyal, Government of India.

- CVBU Pune Plant and Lucknow Plant have won the "Excellent Energy Efficient Unit Award" and Jamshedpur Plant has won the "Energy Efficient Unit Award" at CII-National Award for Excellence in Energy Management - 2014, in Automobile Manufacturing category. The National Excellence in Energy Management Awards were given to industries of various sectors at the hands of Mr. K Pradeep Chandra, (Special Chief Secretary to Government and commissioner for Industrial Promotions – Telangana).

- TECHNOLOGY ABSORPTION, ADAPTATION AND INNOVATION

- Efforts made towards technology absorption, adaptation and innovation

The Company is putting continuous efforts in acquisition, development, assimilation and utilization of technological knowledge through its wide advance engineering project portfolio. The projects in the advance engineering portfolio are focused around the technologies and innovations which the Company might need in the years to come and the current thrust areas being automotive applications like light weighting, fuel efficiency improvement and Hybridization with alternate fuel like CNG, LPG, Ethanol, bio-diesel, electric traction, Hydrogen etc. The Company is actively working on various hybrid and electric power trains for hybrid, electric and fuel cell electric vehicles for both commercial and passenger car applications and making good progress. Producing intelligent, high-performance and eco-friendly vehicles economically at a market-beating pace requires robust, high-performance processes and cutting-edge automotive engineering expertise.

The Company took initiatives by various interventions at Powertrain and vehicle level to improve upon the performance, refinement, meeting and exceeding the current prevalent norms of emission, fuel economy and reduction in carbon footprint of the products launched recently as well as the future products and platforms. The Company focuses on building environmental sustainability and meet the future demand for green vehicles. The Company continues to work on the already initiated new generation powertrain programmes which would meet the stringent future domestic and international emission norms. As a longer term action, the Company has also started taking into cognizance the current CAFÉ (Corporate Average Fuel Economy) and what would the likely future regulations entail on the envisaged future product portfolio. The Company is also pursuing various initiatives, such as the vehicle lightweighting technology, to enable our business to comply with the existing and evolving emissions legislation in the developed world, which we believe will be a key enabler of both reduction in CO2 and further improvement in efficiencies in manufacturing and engineering.

The Company is also currently focusing on bringing safer vehicles to the end customers and the vehicle occupants (both active and passive safety) than the norms currently prescribed for which extensive safety attribute target setting, Computer-Aided Engineering, Simulation and testing capabilities has been baked into plan for delivering the future products on the anvil.

The Company is progressing well in its innovative and constant endeavour to front load the future product development process with concurrent engineering, digital validations and upfront failure mode identification. CAE processes continue to improve confidence in digital validation of the behaviour of physical prototype with a goal of reducing the number of prototypes. Additional infrastructure added in the recent past for high performance computing, continues to support this goal. All relevant development and testing facilities and infrastructure required to support the endeavour like state-of-the-art advanced design studio, rapid proto-type development system, testing cycle simulators, advanced emission test laboratories are being put in place to support this migration of heavier digital product development model.

- Benefits derived as a result of the above efforts

Introduction of new products/processes has helped the Company to meet the emerging market needs and also maintain its technological leadership. By careful selection of the advanced engineering and technology portfolio, the Company intends to capitalise and bookshelf the developed technology for incorporation into the future products for making them more exciting and more attractive to the end customers. Similarly the Company wishes to mitigate all future risks related to technology by timely having appropriate emerging technology on Powertrain, Safety, etc. to meet and exceed all future emissions and vehicular safety norms. The Company also is in a stronger position today with front loading the digital product development and validation which has resulted in operational efficiency, better quality and shorter lead time to market. The introduction of material pair compatibility equipment and corrosion test facility etc. showcases high standards of quality that the Company is focusing on in order to meet customer satisfaction.

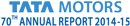

Major technology absorption projects undertaken during the last year includes:

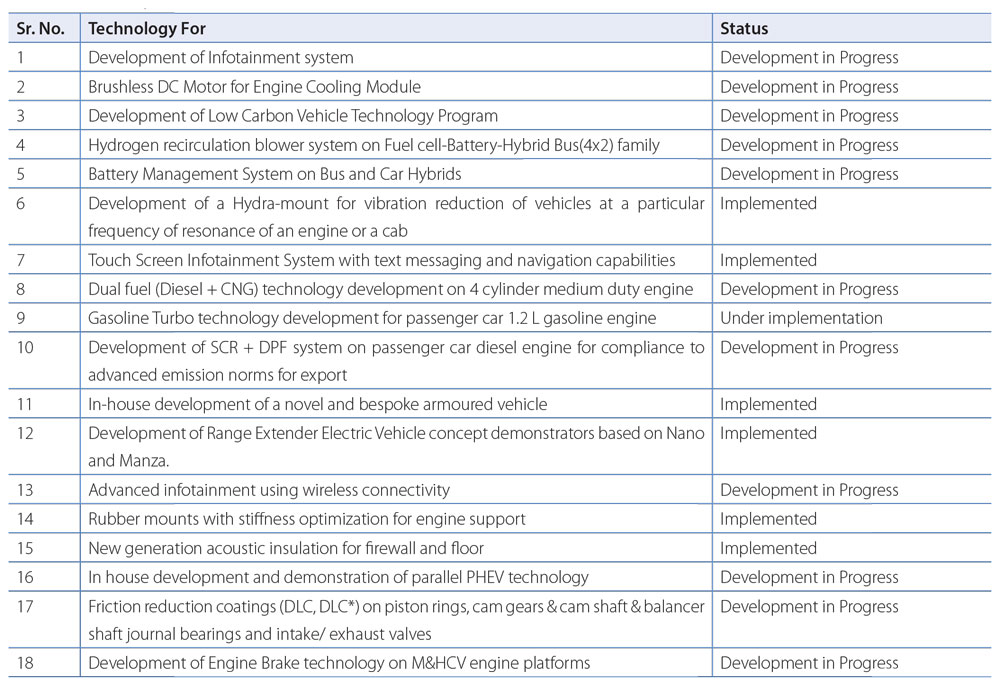

- Major technology imports includes:

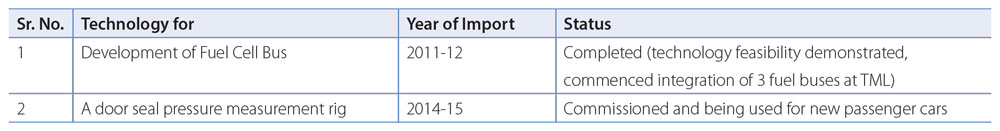

- Research And Development:

Specific areas in which R & D carried out by the Company

Company's R&D is aligned towards developing and acquiring the technology, core competence and skill sets required for robust and timely delivery of the envisaged future product portfolio with leading product attributes across the range of Commercial and Passenger Vehicles. For the Passenger Vehicle product range, the focus is on stunning design, drive experience and connected car technologies and for the Commercial Vehicle product range the focus is to be the market leaders by enhancing fuel efficiency, minimizing total cost of ownership and adaptive to different applications.

All the R&D activities that the Company is currently undertaking takes into account the current and likely future regulatory norms along with meeting and exceeding the prescribed and prevalent vehicle safety regulations. The Company also continues its R&D efforts in developing vehicles which are powered by alternate fuels like CNG, LPG, Bio-diesel, electric traction and Hydrogen. As part of its efforts in this area the Company sponsored the first International Conference on Sustainable Fuels in partnership with TERI. The Company focuses on fulfilling the customers future needs through creativity and innovation supported by systematic technology 'road mapping'.

Benefits derived as a result of the above R&D

The Company maintains requisite R&D facilities, core competence and skill sets enabling it for compliance of regulations and reducing product development time to meet market requirements. Introduction of new products and processes has helped the Company to meet the emerging market needs in terms of design and engineering quality. Increasing use of 'digital validation' techniques has enabled a reduction in the number of physical prototypes required. All existing Company products and engines are compliant with the prevalent regulatory norms. The Company maintains its' focus on safe and crashworthy vehicles.

During Fiscal 2015, the Company filed 86 Patent Applications and 203 Design applications. In respect of applications filed in earlier years, 21 Patents were granted and 5 Designs were registered.

Future Plan of Action

The Company continues its effort on developing new products and technologies to meet growing customer expectations. The existing products will be refreshed at regular intervals to suit upcoming trends. In the long term, the Company is focusing on improving driving pleasure, fuel efficiency, performance and design aesthetics. The Company is coming up with contemporary styling and stunning designs, high performance infotainment systems with IT enabled services, advanced safety and advanced features with the view to delight customers. The Company is targeting to capitalize in different sectors of the market by launching by creating a portfolio of models focused on each segment. Company's R&D is also committed to minimize the environmental impact and carbon footprint of its products and manufacturing operations, with Greenhouse Gas (GHG) emissions in particular. The Company is uniquely placed to meet this commitment, with its comprehensive product line-up and indigenous manufacturing base.

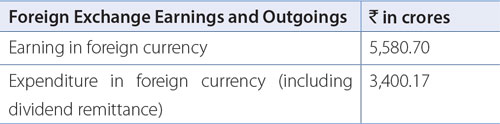

- FOREIGN EXCHANGE EARNINGS & OUTGO

Activities relating to exports

The Company exported 49,936 vehicles during the year.

Export initiatives such as goods, products and services exported include:

- The Company participated in key motor shows and conclaves around the world such as Indonesia International Motor Show (IIMS), Geneva International Motor Show, Algiers Motor Show and Manila Motor Show.

- Tata Prima successfully launched in 5 IB markets in Fiscal 2015 including Sri Lanka, South Africa, UAE, Qatar and Nepal. Launched the Ultra buses in Nepal and Ultra Trucks in Sri Lanka.

- New products customized for key international customer segments were launched – including the Xenon XLT, a lower cost variant in South Asia and the Xenon XT with ESP, a premium variant for Australia which was certified as meeting ANCAP 4 star rating.

- Successfully bagged and executed an order for Defense vehicles and Xenon troop carriers for the UN Mission in Africa and Myanmar Army respectively.

Development of export markets

The New Markets in ASEAN are the Company's focus region for future growth – Indonesia, Australia, Philippines and Malaysia have been opened recently and the volumes are slowly and steadily picking up as the Tata Motors brand is becoming more visible in the market. Vietnam will be another market added to this list in early Fiscal 2015. In addition, the Company has been expanding its presence with the introduction of new products such as Tata Prima, Ultra trucks and buses in some of the key markets to further grow volumes.

For PV, the Company entered into three new markets in Fiscal 2015, viz., Algeria, Philippines and Uruguay, to develop a stronger base for its business going forward. However, some abrupt safety feature mandates for vehicles introduced in Algeria threaten to hamper our plans somewhat. The Company will be attempting to grow its business in South Asia in the coming year, specifically in markets like Sri Lanka and Bangladesh, in addition to Nepal.

Export Plans

The Company plans to focus on growing the export business aggressively in identified geographies by offering customer centric products and strong after sales support.

On behalf of the Board of Directors

CYRUS P MISTRY

Chairman

Mumbai, May 26, 2015