TML (Standalone)

APPROACH TO LONG-TERM VALUE CREATION

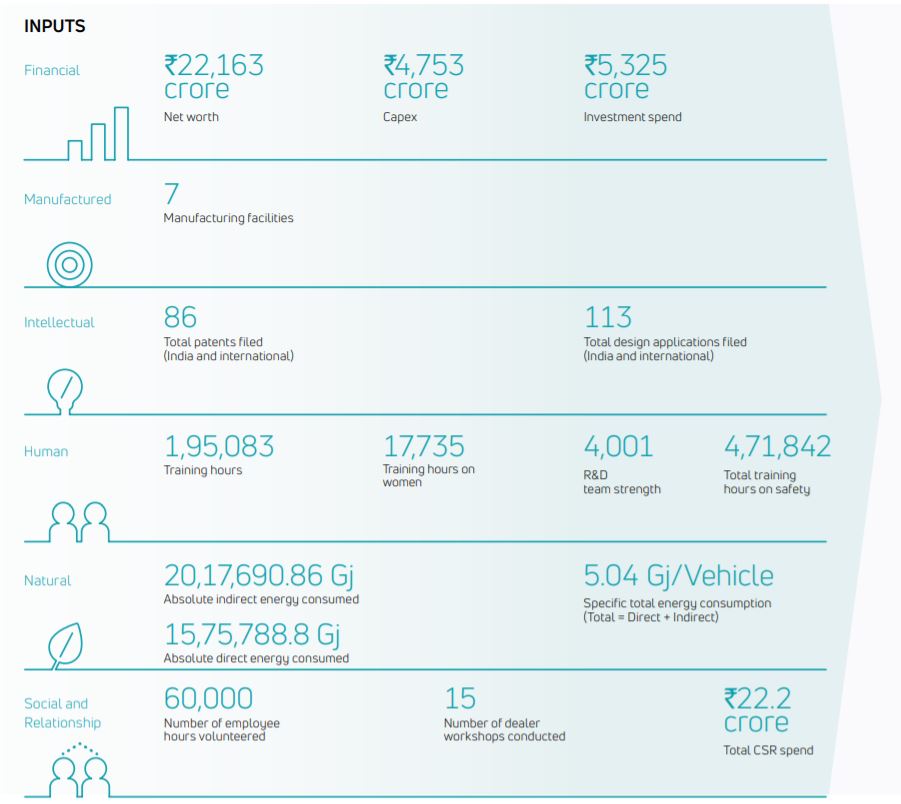

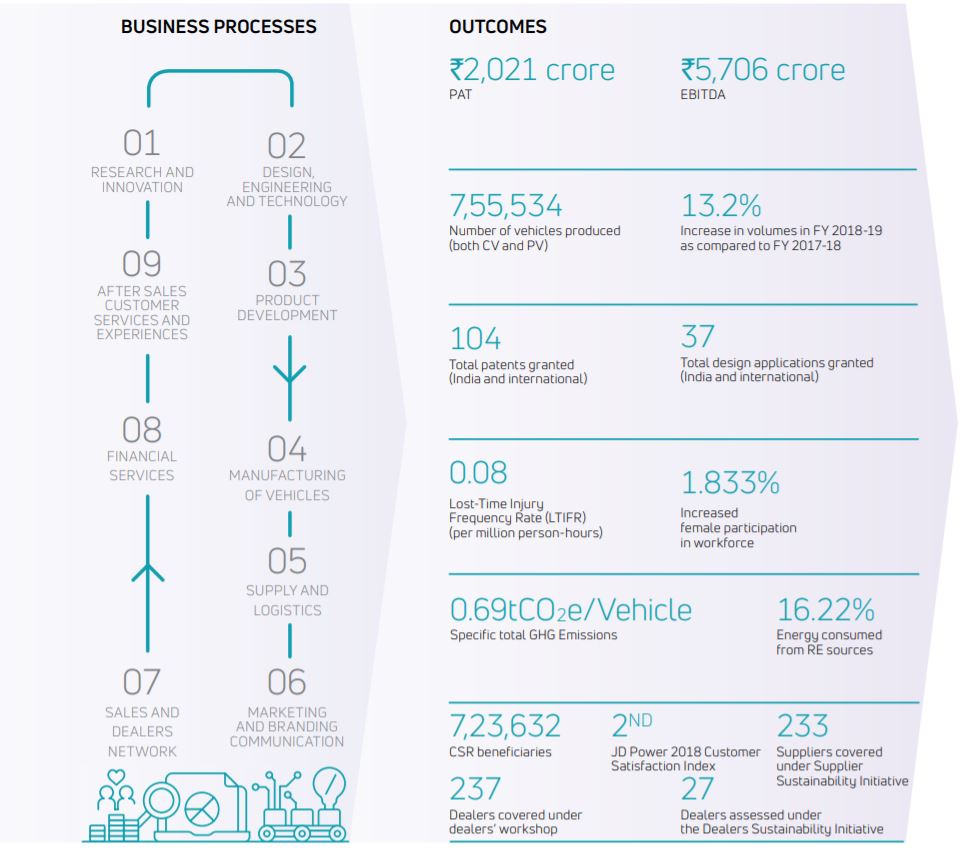

TML (Standalone) is well aligned with its vision of delivering financial growth, while providing sustainable mobility solutions, exceeding customer expectations and creating a highly engaged workforce. Its business processes and activities reflect its ‘integrated thinking’ towards deploying resources and their relationships.

Enhancing Financial Capital

We evaluate our value-creation abilities across multiple capitals and aim to continuously enhance the value it creates.

TML generates direct economic value through its operations, products and services. TML also works towards nation building by contributing towards significant indirect economic impacts, which result in increased economic activity, reduced social disparity and an improved quality of life.

While TML continues focusing on improving cash flows and cost competitiveness, it makes significant investments in product innovation, process improvement and technology development to leverage opportunities in the changing market scenario to stay ahead of the curve.

TML spent Rs.2,965.25 crore in R&D for developing clean technology vehicles, transitioning from BS III to BS IV, and implementing mandatory safety features. We also made substantial investments in clean and sustainable mass transportation such as hybrid buses and SCV for last mile connectivity. These investments focus on increasing profitability while creating far-reaching and positive economic impacts.

Progressing on excellence in manufacturing

Efficiency in manufacturing is closely associated with TML cost competitiveness. As part of its Turnaround 2.0 plan, TML emphasises the use of efficient manufacturing technologies, modular platforms and improving efficiency in its supply chains.

Innovation deeply embedded in the DNA

Strong R&D teams – comprising leading scientists, engineers, designers and technicians based out of multiple locations globally – focus on worldclass engineering and nextgeneration technologies.

We recently also rolled out the Turbotronn 3L, 3.3L and 5L series diesel engines for CVs. These new generation engines offer an unrivalled combination of fuel efficiency, performance and refinement, coupled with the latest technology available globally. The Revotron and Revotorq engines sport the first-in-segment multi-drive modes; eco, city and sport.

The core of TML's business is its manufacturing capability. Manufactured capital encompasses physical infrastructure including plants, buildings, machineries, equipment, tools and technology as well as infrastructure owned by third parties such as warehouse and logistics facilities.

With the emergence of new-age sustainable mobility solutions, TML is preparing its manufacturing capabilities for the future. On one hand, TML has developed the OMEGA and ALFA modular architectures, which can also provide the platform for manufacturing EVs. On the other, it is transforming as an organisation by building in operational efficiency using modular architecture, managing costs and embedding a culture of innovation in businesses and processes. It is conducting a critical review of internal resources and rolling out productivity improvement and fixed cost reduction initiatives. All TML plants are ISO 14001:2015 and OHSAS 18001:2007 certified.

TML's ability to innovate is demonstrated by its frugal engineering, path-breaking vehicles, new-age concept cars, and award-winning engines.

TML's state-of-the-art R&D centres and design studios are located in Pune (India), South Korea, Italy and the UK, and have many firsts to their credit. TML houses Asia’s first anechoic chamber, India’s first full vehicle crash test facility and the country's only full climate test facility.

POWERTRAINS

With the launch of Nexon, TML added two power-packed, performance-oriented engines to the powertrain family – the 1.2L Revotron turbocharged petrol engine and the 1.5L Revotorq diesel engine.

DESIGN

At Tata Motors, design is not just about developing new surfaces, blending colours, materials and finish, but is also about creating compelling products that offer the latest technology-rich features and deliver high performance.

In continuation with our transformation journey, TML had introduced the IMPACT Design philosophy for its PVs in 2016. In January 2018, TML introduced the second version – IMPACT Design 2.0 – during the 150th anniversary of the Tata group. IMPACT Design 2.0 is a sharper and more contemporary iteration of Tata Motors’ renowned design language.

The design language extends to TML's CVs as well. Termed as the Premium Tough Design philosophy, it combines visual richness and sophistication with robustness and reliability.

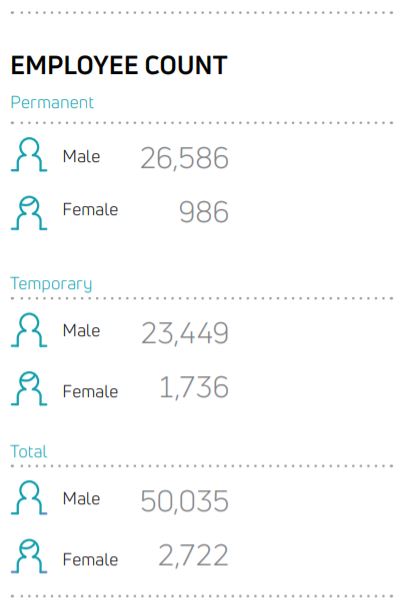

Preparing future leaders

TML invests in attracting and retaining the best talent. It works towards ensuring their holistic development by empowering them with resources that promote work-life balance. TML works towards enabling professional development of high potential and managerial staff through systematic career management programmes. During the year, 2,100 joined TML at various permanent positions and 44,061 at temporary positions while 1,681 left the organisation.

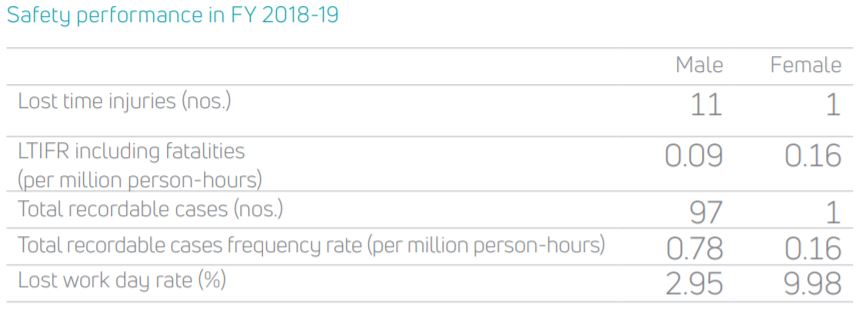

SAFETY

Several initiatives were taken across TML locations to enhance safety. These include implementation of Proactive Safety Index (PSI), monitoring of driving safety behaviour (SDI), i-Care programme, senSHEtise programme on women safety, second party SHE audits, celebration of Road Safety Month 2019 and National Safety Month 2019. The PSI and SDI are two effective measures of safety compliance within and outside plants, respectively.

The i-Care initiative was directed towards developing behavioural safety. Apart from internal and third-party audits, employees from one plant carry out audits in another plant to improve safety governance in the system.

Our safety programmes include not only our senior executives, but are also used to sensitise our suppliers, vendors and channel partners. TML believes that what can be measured, can be improved. This is especially true for its safety performance.

TRAINING AND DEVELOPMENT

The automotive sector is witnessing transformational changes with the emergence of electrified, shared and autonomous vehicles. TML, thus, needs to continuously update and upgrade, both technically and functionally, its learning and development programmes in line with the changing needs. A learning governance body called the Learning Advisory Council (LAC) is entrusted with the responsibility of ensuring business relevance and value. The LAC designs, implements and periodically reviews the learning agenda.

For senior executives and officers, TML associates itself with third parties such as the National Employment Enhancement Mission (NEEM) and designed programmes on vehicle integration in collaboration with the Government.

TML's Chief Learning Officer is responsible for managing skill development and training needs of senior executives and officers; the training and development initiatives are managed through the Learning Management System (LMS) platform.