- GOVERNANCE RELATED TO BR

- Indicate the frequency with which the Board of Directors, Committee of the Board or CEO to assess the BR performance of the Company. Within 3 months,3-6 months, Annually, More than 1 year

Executive Committee reviews and assesses the various aspects of BR performance of the Company. The frequency of Executive Committee meetings for BR Review is 3-6 months.

Please refer "Corporate Governance" section of Company's Annual Report Fiscal 2016 for various Board Committees and their roles and responsibilities. - Does the Company publish a BR or a Sustainability Report? What is the hyperlink for viewing this report? How frequently it is published?

Tata Motors has been publishing annual Sustainability Reports in accordance with globally renowned Global Reporting Initiative (GRI) framework. These reports also serve as the Company's Communication on Progress (COP) as part United Nations Global Compact (UNGC) signatory reporting obligations and have been aligned with the National Voluntary Guidelines on Social, Environmental and Economic Responsibilities of Business, released by Ministry of Corporate Affairs. The Company also published Annual CSR Report this year to highlight the community engagement strategy and performance. The Company's Sustainability and CSR Reports can be viewed at http://www.tatamotors.com/sustainability/sustainability.php.

- Indicate the frequency with which the Board of Directors, Committee of the Board or CEO to assess the BR performance of the Company. Within 3 months,3-6 months, Annually, More than 1 year

SECTION E: PRINCIPLE-WISE PERFORMANCE

Principle 1: Ethics, Transparency and Accountability- Does the policy relating to ethics, bribery and corruption cover only the company? Yes/No. Does it extend to the Group/Joint Ventures/Suppliers/Contractors/NGOs/Others?

Tata Motors has adopted the Tata Code of Conduct (TCoC) to remain consistently vigilant and ensure ethical conduct of its operations. All internal and external stakeholders of the Tata Group are expected to work within the framework of the TCoC. The Company ensures compliance of ethical standards by its vendors and contractors through appropriate clauses in its work contracts to which they are obligated. Generally, the contract includes clauses in relation to Human Rights Protection, Corruption practices and other things related to ethics. Training and awareness on TCoC is provided to all employees and relevant stakeholders are also made aware of the same from time to time.

The Company also has a whistle blower mechanism, which is being governed by the Whistle Blower Policy. Through this it has placed mechanisms for ensuring confidentiality and protecting the whistle blower from any harassment/victimization. The policy covers instances pertaining to any unfair practice like retaliation, threat or intimidation of termination/suspension of service, disciplinary action, transfer, demotion, refusal of promotion or the like including any direct or indirect use of authority to obstruct the Whistle Blower's right to continue to perform his duties/functions including making further Protected Disclosure. The Policy is directly monitored by the Chairman of the Audit Committee and the Chief Ethics Officer.

The Company has an ethics helpline where employees can place anonymous complaints against ethics violations as per the Policy of the Company. The ethics helpline can be reached in the following ways:

Ethics Hotline: 1800 224440/022-2287 1839.

Oral reports will normally be documented by the Chief Ethics Counselor/Chairman of the Audit Committee accessing the voice mail by a written transcription of the oral report

Written application to Ethics and compliance:All concerns can be reported to Chief Ethics Counselor/Chairman of the Audit Committee in Hindi, English or any regional language.

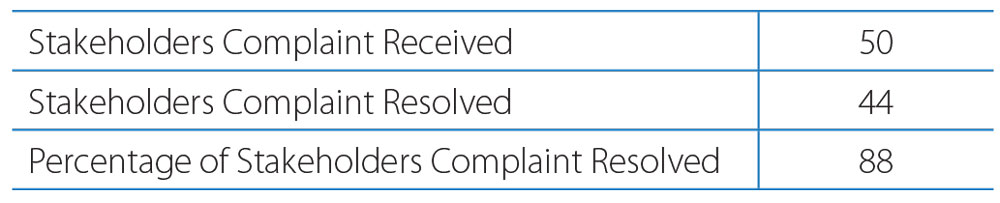

- How many stakeholder complaints have been received in the past financial year and what percentage was satisfactorily resolved by the management? If so, provide details thereof, in about 50 words or so.

*Includes TCoC concerns, investor complaints and customer complaints

The Company has setup an investor grievance mechanism to respond to investor grievances in a timely and appropriate manner. The investor grievances are also reviewed at the Board level by an Investors' Grievance Committee and immediate action is taken to resolve the same. The Tata Code of Conduct concerns are resolved through internal review mechanism by Ethics Counselor and Senior Management. Both the Commercial Vehicles Business unit and Passenger Vehicles Business Unit have established robust customer care systems which track customer complaints and responds to them in the minimum time possible.

PRINCIPLE 2: Product Life Cycle Sustainability

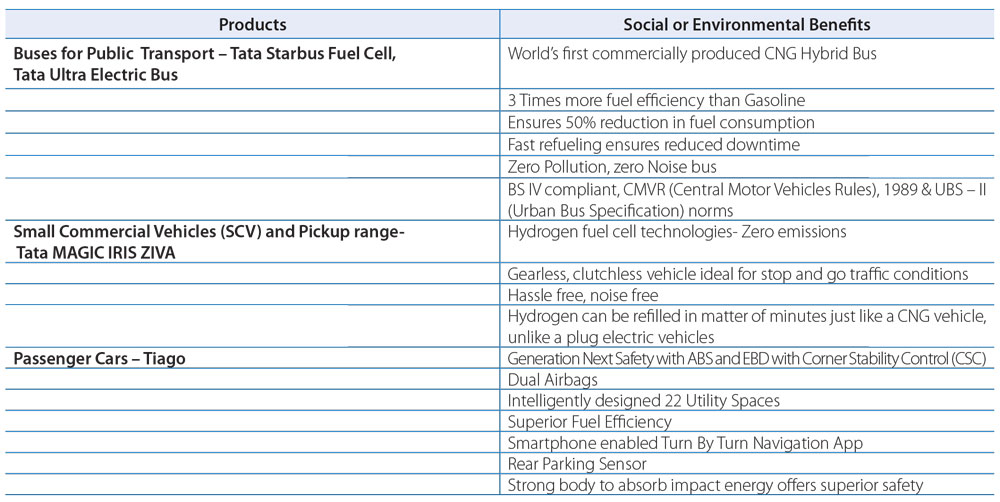

- List upto 3 of your products or services whose design has incorporated social or environmental concerns, risks and/or opportunities.

Tata Motors is a leading automobile manufacturer of India and has played a significant role over the years in contributing to economic growth of the nation through its commercial vehicles and passenger cars which transport people, goods and help deliver services on time. The Company realizes its responsibility as a growth enabler and endeavors to create vehicles which will promote entrepreneurship. The Company is also cognizant of the environmental impacts caused during production and lifecycle of its products and continually strives to innovate to reduce such impacts. Tata Motors has signed a contract to supply 25 Tata Starbus Diesel Series Hybrid Electric Bus with Full Low floor configuration, with the Mumbai Metropolitan Region Development Authority (MMRDA) – the single largest order awarded for Hybrid Electric Vehicle Technology. Below are few of the products which have been designed to address social or environmental concerns, risks and/or opportunities.

- For each such product, provide the following details in respect of resource use (energy, water, raw material etc.) per unit of product (optional):

- Reduction during sourcing/production/distribution achieved since the previous year throughout the value chain?

There is a continual eff ort to reduce the life cycle impacts of the vehicles across the value chain. The Company focuses on researching, developing and producing new technologies, such as hybrid engines and electric cars. It is also investing in development programs to reduce fuel consumption through the use of lightweight materials, reducing parasitic losses through the driveline and improvements in aerodynamics. It closely works with its suppliers and vendors to reduce the environmental impacts in the sourcing stage. Use of returnable and recyclable packing solutions for most of the components has been a key initiative to manage cost and quality, reduce material use and avoid waste generation. This also contributes towards reduction of climate change impacts by avoiding the use of wood for packaging of components. Vehicle weight reduction through new and improved technologies remains the focus of the Company to achieve higher fuel efficiency as well as a reduction in environmental impact. Some of the key areas that we are currently working are; use of hollow camshafts, low density polyamides and magnesium alloys.

- Reduction during usage by consumers (energy, water) has been achieved since the previous year?

The class leading fuel efficiencies of the Company's vehicles enable the customers to achieve fuel savings which translate into cost savings as well. This year witnessed the launch the all new REVOTRON engine which epitomizes the FuelNext philosophy of the Company. It is developed using a range of eco-friendly and future oriented technologies. It also incorporates latest know-how like multi drive modes, allowing the best of economy and driving pleasure. The Company's value proposition in the commercial vehicles is aimed to create vehicles with lowest overall cost of ownership. The Recon business, which reconditions aggregates, extends the life of the aggregates and eliminates the use of fresh resources that might have been consumed for new aggregates.

- Reduction during sourcing/production/distribution achieved since the previous year throughout the value chain?

- Does the company have procedures in place for sustainable sourcing (including transportation)? If yes, what percentage of your inputs was sourced sustainably?

The Company continually works with its vendors and suppliers to reduce the environmental impacts of sourcing. The Company has an Environment Procurement Policy to engage with its value chain partners on environmental sustainability. Significant initiatives have been taken to reduce the packaging mpacts in the supply chain by using recycled/returnable packaging solutions for various components sourced. Transportation and logistics optimization is an ongoing activity to reduce the related environmental impacts. The Pantnagar and Sanand plants have created a vendor park model wherein the key vendors are situated surrounding the plant. This not only enables to optimize the production related costs but also significantly reduces the environmental impact of transportation of components.

- Has the company taken any steps to procure goods and services from local & small producers, including communities surrounding their place of work? If yes, what steps have been taken to improve their capacity and capability of local and small vendors?

During the year, the Company has procured 55.09% of the materials (by value) from local sources, where local is defined as the state in which the manufacturing plant is established. The Company takes significant initiatives in enhancing the capabilities of local and small vendors. Through the AA policy initiatives, this year the Company has added 10 new SC/ST entrepreneurs in the supply chain and extended business of Rs. 9.79 crore to them.

To ensure reliable and responsible suppliers for automotive production and service parts, Tata Motors expects all our suppliers to adopt the ISO 9001/TS 16949 quality management system frameworks. We also encourage our dealers to adopt quality, environmental and safety management systems. We conduct awareness sessions for suppliers on social and environmental issues. Suppliers are provided with managerial and technical assistance to train them on practices and procedures that will ensure improvements in Productivity, Quality, Cost, Delivery, Safety and Moral (PQCDSM).

- Does the company have a mechanism to recycle products and waste? If yes what is the percentage of recycling of products and waste (separately as <5%, 5-10%, >10%). Also, provide details thereof, in about 50 words or so.

It is the Company's ongoing endeavor to have a mechanism to recycle our products and limit the waste arising out of production of vehicles. The Company has initiated well defined program Prolife. Our objective is to reduce the waste and to minimize the need of raw materials to produce a brand new item. In Fiscal 2016 total of 23115 components were reconditioned. The re-conditioned long blocks are also being exported to international markets. Hazardous waste is disposed as per regulatory requirements through the Common Hazardous Waste Treatment, Storage & Disposal Facilities (CHWTSDF), Authorized Re-cyclers and co-processing in cement plants.