ANNEXURE 3

Particulars of Conservation of Energy, Technology Absorption and Foreign Exchange Earnings and Outgo

[In terms of Section 134 (3) (m) of the Companies Act, 2013 read with Rule 8 of the Companies (Accounts) Rules, 2014]

- CONSERVATION OF ENERGY

The Company has always been conscious of the need for conservation of energy and has been sensitive in making progress towards this end. Energy conservation measures have been implemented at all the plants and offices of the Company and special efforts are being put to undertake specific energy conservation projects like:

- The steps taken or impact on conservation of energy:

- Waste Heat Recovery System to recover waste heat from exhaust flue gases of surfacer & finish paint baking ovens, conversion of indirect fired baking ovens into direct fired burner of baking ovens, conversion of electrical heating into Natural Gas Heating System for washing machines

- Use of energy efficient 40W LED Batten fittings for task lighting, 100W LED High bay for General Lighting, 19W LED tube lights in Office area, installation of 42W LED street lights, installation of 142W LED flood light fittings

- Elimination of pump operation by using gravity flow system, resizing of hydraulic power pack pump

- Compressed Air Pressure optimization at paint shop and at other shops, use of portable small compressors for low compressed air requirement on holidays, installation of Shut Off Valves in compressed air network, downsizing of motors and Delta to Star conversion of motors

- Installation of variable frequency drives for various applications like Blowers, Pumps & Air supply plants

- Use of infrared sensors & timers for on-off control of industrial fans, lighting system of inspection booths and fresh air blower operation. Modification in electrical logic for automatic switching on-off operation of hydraulic motors, coolant pumps, blowers etc., optimization of AC plant operations.

These efforts have resulted in electrical energy saving of Rs. 1.47 crores. units, fuel saving – Light Diesel Oil 6 KL, LPG/Propane 586.32MT and Natural Gas 1.34 Lakh SCM. The whole effort resulted in cost savings for the Company of around Rs. 14.5 crores and annual CO2 emission reduction of 13,960 tCO2e.

- The steps taken by the Company for utilizing alternate sources of energy:

- Company's CVBU Pimpri Plant utilized total wind power generation of 2.25 crores units (i.e. equivalent CO2e reduction of 22,125 tCO2e) for Fiscal 2016 from 'captive wind power' projects of 21.95 MW capacity. This resulted in net savings of Rs. 8.9 crores in electricity charges. Also Company's PVBU Sanand Plant utilized wind energy of 0.68 crores units (equivalent CO2e reduction of 5,573 tCO2e) purchased through TPTCL for Fiscal 2016, this resulted net savings of Rs. 0.478 crores in electricity charges

- Renewable Energy Certificate (REC): Company's 21.95MW wind power project is registered under REC Scheme. Cumulative 63,432 RECs generated; out of which 40,517 RECs sold through auction, cumulative benefit is of Rs. 5.85 crores

- Roof Top Solar PV Power Plant 1.8MWp has been installed & commissioned on Roof Top of Office Blocks at the Company's, Pune Plant (CVBU& PVBU). Annual Solar Power Generation is 21.29Lakh Kwh (equivalent CO2e reduction of 2,097 tCO2e) for Fiscal 2016, resulted net saving of Rs. 0.59 crores in electricity charges

- Roof Top Solar PV Power Plant 2.0MWp has been installed & commissioned on Roof Top of Office Blocks at the Company's, Sanand. Annual Solar Power Generation is 17.30Lakh Kwh(equivalent CO2e reduction of 1,709 tCO2e) for Fiscal 2016, resulted net saving of Rs. 0.17 crores in electricity charges.

All above efforts have resulted into consolidated total CO2 emission reduction of 35,099 tCO2e for Fiscal 2016.

- Water and waste related performance:

- During the year 4202 MT of hazardous was sent for final disposal to offsite facility, while a total of 1044 MT of hazardous waste was recycled/reused through offsite authorised facility or by energy recovery

- During the year 6.79 million m3 of fresh water was consumed and 0.64 million m3 of generated effluent was recycled back into process.

- The capital investment on energy conservation equipments:

The Company has invested about Rs. 6.92 crores for achieving these results.

Awards/Recognitions received during the year is as below:

- The Company's Dharwad Plant has bagged the "1st Prize" of National Energy Conservation Award 2015, in Automobile Manufacturing category by Bureau of Energy Efficiency (BEE), Ministry of Power, Government of India

- The Company's Chikhli car plant has won Vasundhara Award -2015 under the "Large Scale Industry" Category from Government of Maharashtra Pollution Control Board

- The Company's Jamshedpur Plant and Pantnagar Plant have been rated GOLD under the CII-GreenCo - Green Company Rating System

- The Company's CVBU Pune Plant, Jamshedpur Plant and Lucknow Plant have won the "Excellent Energy Efficient Unit Award" at CII-National Award for Excellence in Energy Management-2015, in Automobile Manufacturing category

- The Company's CVBU Pune plant, Jamshedpur Plant, Lucknow Plant and Pantnagar Plant won the Good Green Governance (g3) Awards 2015 instituted by 'Srishti' Publications, New Delhi. The award recognizes organizations for going beyond mere legal compliance for environmental protection

- The Company's Pune Plant received CII-GBC GreenCo Best Practices Award-2015:- CII-GBC Assessor's Panel has recognized the Company for the excellent efforts in "Best Practices in Life Cycle Assessment" for the GreenCo Best Practices Award. The Company Pune plant was presented a Shield and a Certificate as a recognition for the best practices implemented.

- The steps taken or impact on conservation of energy:

- TECHNOLOGY ABSORPTION, ADAPTATION AND INNOVATION

- Efforts made towards technology absorption, adaptation and innovation

The Company uses a three-horizon strategy for managing its engineering and technology initiatives. The first-horizon involves products that the Company is working on currently, to bring to the market. The second-horizon involves researching known technologies that the Company may not be entirely familiar with at the present time but are needed for our future products. And the third-horizon is for 'blue sky' research projects and there are a number of projects aimed at fostering a culture of innovation in the Company.

Besides, its own ecosystem spanning across India, the UK and Italy, the Company also has tie-ups with various Universities based out of India, University of Warwick in the UK, and joint efforts with institutions in the United States. In India, as part of its efforts in this area the Company has signed a Memorandum of Understanding with IIT Bombay (IITB) and College of Engineering Pune (COEP) to undertake collaborative research on live projects and to create a technological partnership.

The main endeavour which the Company has is to continuously keep scanning for innovative projects in the third and second horizon to integrate the promising ones to the main stream projects in the first horizon.

For example, some of the forward-looking technology programmes that the Company is concentrating on are:

- UK Government funded technology program on autonomous vehicles.

- ADAS and Safety related features likely to come in.

- Internet and associated technologies on connectivity like apps, telematics, diagnostics, analytics, etc.

- Alternate fuels like CNG, dual fuel, hydrogen.

- Hybridization, xEVs and associated technologies.

- Composites, light weighting and fuel efficiency improvement related technologies.

- Benefits derived as a result of the above efforts:

The Company continues to strengthen its capabilities across the technology domain to meet the emerging and future market needs. By careful selection of the advanced engineering and future technology portfolio, the Company intends to capitalize and bookshelf the developed technology for incorporation into the future products for making them more exciting and more attractive to the end customers.

The Company also wishes to mitigate all future risks related to technology by timely having appropriate emerging technology on emissions, FE enhancement, powertrain, safety, connectivity, infotainment, telematics, green initiatives etc., to meet and exceed all future emissions and vehicular safety norms.

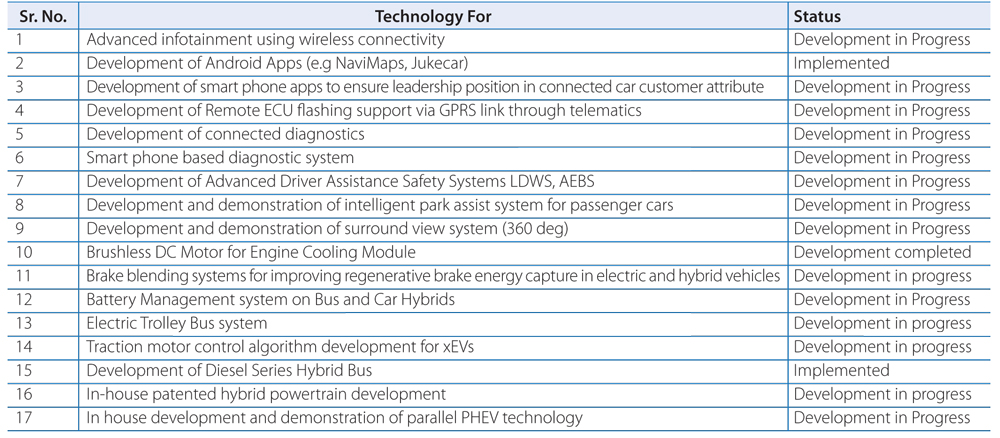

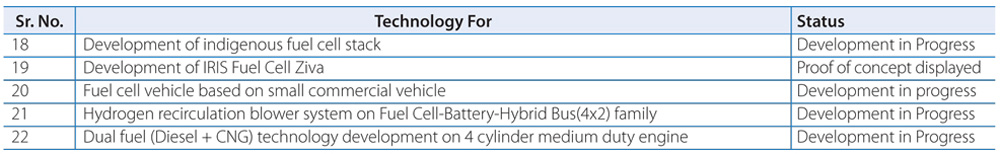

Major technology absorption projects undertaken during the last year includes:

- Major technology imports includes:

- Research and Development:

- Efforts made towards technology absorption, adaptation and innovation

Specific areas in which R&D carried out by the Company

The Company is mainly focused on specific areas of R&D and Engineering by which it can strengthen its HorizoNext Philosophy. For passenger cars, the main focus areas are in the domain of creating stunning design, pleasurable driving experience and connectivity. Therefore, the R&D portfolio is aligned towards developing technologies, core competence and skill sets in these specific domains to secure impactful and timely delivery of the envisaged future products with leading product attributes. For commercial vehicles, in addition to design, the main focus areas are total cost of ownership to be a market leader in application specific fuel efficiency and to deliver high performance and reliable products.

Focus areas of Company's R&D also evolves around R&D infrastructure development and being timely future ready for future emissions and vehicular safety norms.

For example, some of the forward looking R&D programmes that the Company is concentrating on are:

- Hybrid drive systems developed/being developed for both passenger and commercial vehicle applications like battery packs, transmission, traction motors, etc

- Connectivity which integrates mobile devices into the vehicle and provides a platform for infotainment, telematics and more

- Selective ADAS technologies for market specific implementation like the once shown in Auto Expo 2016 - Collision Mitigation System (CMS) and Lane Departure Warning System (LDWS), etc

- Alternate fuels like Fuel Cell bus demonstrated in Auto Expo 2016

- Focus on Fuel Efficiency and Total Cost of Ownership

- Design of indigenous fuel cell technology with the other Tata Group companies

- Investment in testing facilities for hybrid powertrain and pilot manufacturing facilities for battery modules and packs

- Light weighting and reliability improvement projects across the range.

Benefits derived as a result of the above R&D

Such efforts on R&D have secured a host of benefits for the Company in terms of being up to date with state of the art in technology front. These technologies and innovations would strengthen the Company's position in commercial vehicles and would contribute in repositioning and transforming passenger vehicles to compete at a global level.

The recently launched Tiago Passenger Car received critical recognition from media and customers for its attributes on design, connectivity, driving dynamics. Similarly, recently launched Signa range of commercial vehicles boosts of superior in-cab experience, proven and reliable drivetrains and future looking inbuilt telematics.

The Company's direct benefit from R&D spanning across over a decade of design effort in developing series hybrid bus, the Company has won the order to deliver 25 diesel series hybrid electric vehicles to the Mumbai Metropolitan Region Development Authority (MMRDA). This is the largest order for hybrid buses in India till date. Once the hybrid buses start running in Mumbai, the Company expect that further orders from other cities might start coming in.

The Company is also developing full electric buses based on the series hybrid bus platform. Given the increased impetus on public transportation and the concern for harmful emissions from vehicles, the market for electric buses are expected to grow rapidly and the Company is fully equipped to cater to that segment.

A fleet of fuel cell buses are being built by the Company with support from Department of Scientific and Industrial Research (DSIR) for demonstration of fuel cell technology. The fuel cell bus fleet will enable the Company to evaluate the technical and economic challenges of making hydrogen-based public transportation a reality in India. Hydrogen fuel cell buses could provide complete zero emission transport for cities without the heavy battery packs needed for serving the daily range of bus operation.

During Fiscal 2016, the Company filed 116 Patent Applications and 37 Design applications. In respect of applications filed in earlier years, 21 Patents were granted and 103 Designs were registered. Both filing and grant details include national and international jurisdictions.

Future Plan of Action

The Company will continue its endeavour in R&D space to develop technologies, skill set and competence which will help the Company meet future product portfolio requirements. One of the main future initiatives in this direction would be platform approach creating bill of material and bill of process which has high degree of commonality to reduce complexity and enhance the scale.

Also, the Company will aim at timely and successful conclusion of the technology projects so that they start getting inducted in the mainstream products leading to a promising future product portfolio.

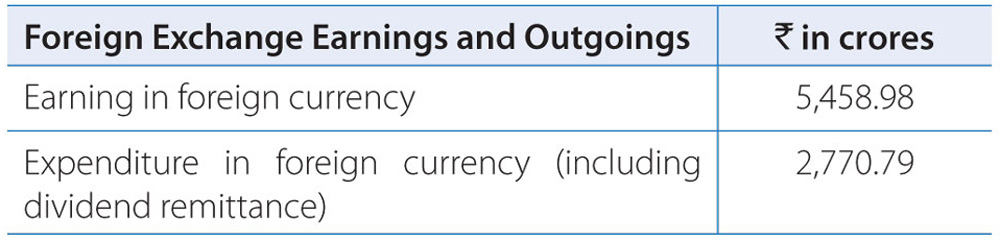

- FOREIGN EXCHANGE EARNINGS & OUTGO

Activities relating to exports

The Company exported 58,058 vehicles during the year.

Export initiatives such as goods, products and services exported include:

- Company participated in key motor shows and conclaves around the world such as the Colombo Motor Show, Nepal Automobile Dealers' Association (NADA) Auto Show, Thailand Motor Expo, Thailand Defence Expo and Malaysia Truck & BusComponents Expo.

- Tata Prima successfully launched in 3 additional IB markets in Fiscal 2016 including Kenya, Uganda and Bangladesh. Launched the Ultra buses in Sri Lanka, Ultra Trucks in Bangladesh and the Elanza bus in the UAE. Also launched the Ace Mega in Nepal and the Ace Express in Sri Lanka.

- Successfully bagged and executed defence orders for Xenon troop carriers for the Myanmar Army and Xenon XT for the Botswana defence Force.

- The 2nd edition of Tata Motors One World - International CV Distributor Meet, was held at JW Marriott, New Delhi from March 20-22, 2016. The event saw attendance by over 300 guests from across 25 countries.

Development of export markets

The new markets in ASEAN are the Company's focus region for future growth – Indonesia, Australia, Philippines and Malaysia have been opened recently and the volumes are slowly and steadily picking up as the Tata Motors brand is becoming more visible in the market. Vehicle assembly in Vietnam was started in Fiscal 2016 and retails will commence from beginning of Fiscal 2017 onwards.

In addition, the Company has been expanding its presence with the introduction of new products such as Tata Prima, Ultra trucks and buses in some of the key markets to further grow volumes.

The Company commenced exports of passenger vehicles to Bolivia in Fiscal 2016 towards expanding footprint across Latin America. The Company was able to secure a government order to supply 219 Indigo cars to the Ministry of Interior in Uruguay. In Sri Lanka, Tata passenger vehicles scaled up from the 8th position in Fiscal 2015 to the 4th position in Fiscal 2016. The Company also consolidated its position in Nepal during Fiscal 2016, notching up the 4th position with a market share of over 9.0%. Despite being in Bangladesh only since 2011, the Company is now also among the Top 5 brands in passenger vehicles there with a market share of over 3.0% rising from the No.11 position in Fiscal 2015. Various customer-centric initiatives for passenger vehicles were rolled out across several markets: 48-hour parts supply guarantee, 24x7 roadside assistance, toll free call centers, express service, Tata Motors Connect app and automated service and warranty expiry reminders. The Company participated in the Geneva Motor Show 2016, showcasing the Tiago, Hexa and Kite 5 compact sedan.

Export plans

The Company plans to focus on growing the export business aggressively in identified geographies by offering customer centric products and strong after sales support.

On behalf of the Board of Directors

CYRUS P MISTRY

Chairman

Mumbai,

May 30, 2016