35

72nd Annual Report 2016-17

Now, the Company is working to lead in electrification,

to achieve the scale required to remain competitive

globally. The driving force of this transformation is the

organisation’s culture of innovation.

JLR is introducing its standardised framework to

overseas sites as a way of directing cross-functional

collaboration and ensuring the deployment of

the right capabilities needed to manufacture our

products.

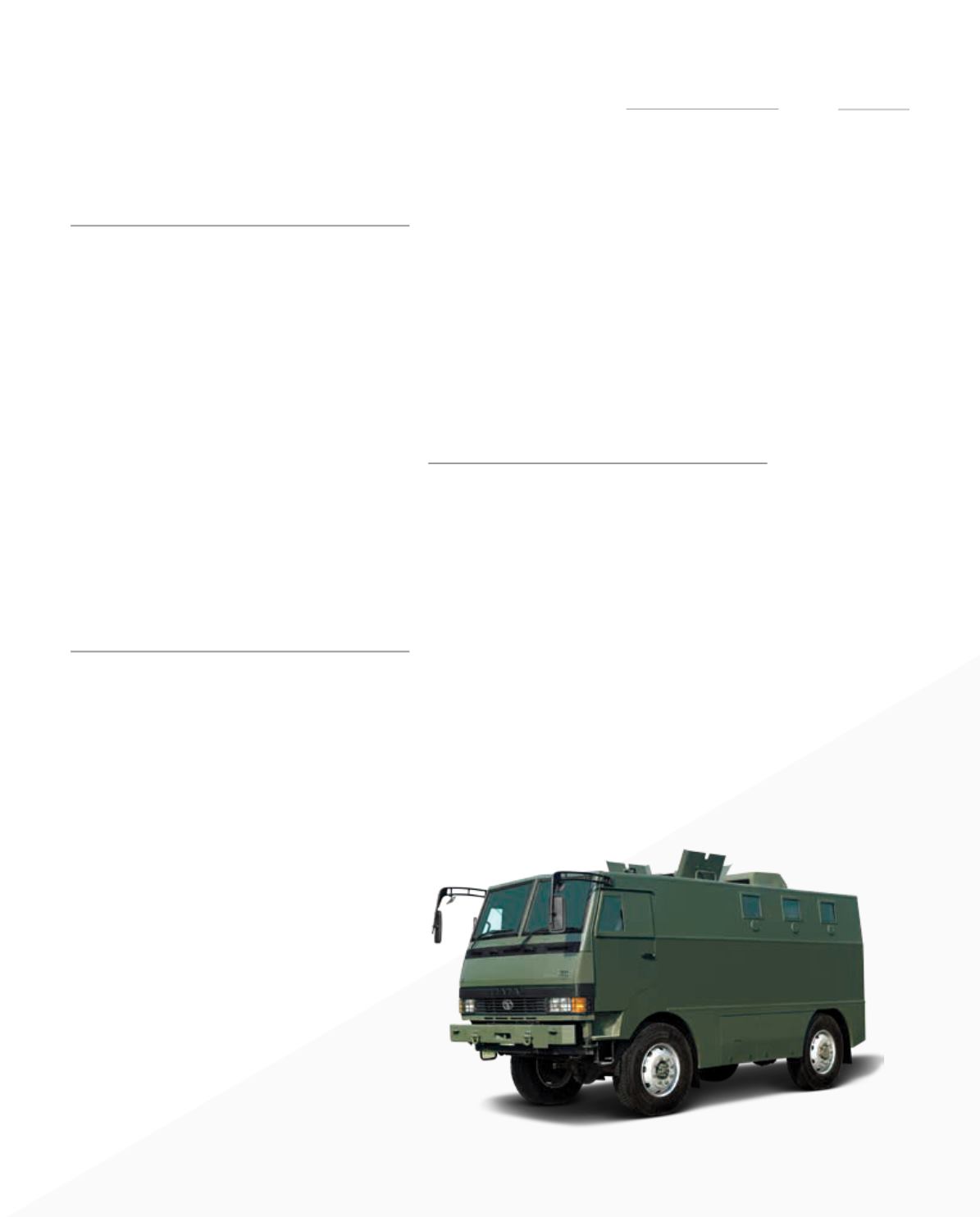

SPEARHEADING INDIGENOUS

DEFENCE TECHNOLOGY

Tata Motors’ Defence Solutions offers its customers

a wide range of vehicles in the light, medium and

heavy category. These include Logistics, Tactical,

Armoured and Specialist vehicles, with lowest life-

cycle maintenance cost, supported by the Company’s

vast pan-India service network, ensuring maximum

operational readiness.

At TML, we are leading a consortium that is bidding

for the ‘future infantry combat vehicle’ (FICV) project

worth $10-billion. Tata Motors, Bharat Forge and

General Dynamics Land Systems have come

together for this initiative.

BUILDING A NEW ROADMAP IN THE CV SPACE

A comprehensive strategy has been developed in CVs

to build on the leadership position. This involves :

• Investments planned across product segments

leading to regular and class-leading product

interventions.

• Accelerate front line sales efforts to gain

market share.

• Customer-centric, judicial mix of EGR (Exhaust Gas

Recirculation) & SCR (Selective Catalytic Reduction)

technology offerings.

• Structural initiatives to improve capacity utilisation

and productivity.

• Establishing TML as a full-range defence solutions

provider.

• Working on the road map prepared for 20%

topline contribution from exports.

REVAMPING THE MANUFACTURING PROCESS

The change in the manufacturing approach primarily

concerns two aspects - achieving commonality in the

bill of materials across PVs and shifting to an advanced

modular platform where the same line can be used to

make multiple products. The cost-structure analysis is

being driven internally by ImpACT projects.

At JLR, the first phase of transformation is complete,

with costs reduced across the business through

process excellence and architecture efficiencies.